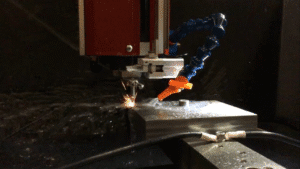

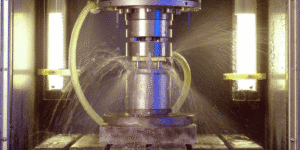

Electrochemical milling, a subset of electrochemical machining (ECM), is a cutting-edge manufacturing technique that uses the principles of electrolysis to remove material from a workpiece. Unlike conventional machining, ECM operates without direct physical contact between the tool and the workpiece. Instead, an electrolyte fluid and a specially designed cathode tool are used to dissolve material from the workpiece, which serves as the anode.

One of ECM’s most significant advantages is that it operates without generating heat. This characteristic eliminates thermal stress and potential damage to the workpiece, common issues in traditional machining. Electrochemical milling is ideal for machining complex geometries and hard-to-machine materials, including superalloys like Inconel, which are commonly used in high-performance industries such as aerospace and automotive.

As manufacturers seek ways to achieve precision and superior surface finishes, ECM has gained prominence as a reliable and efficient process in creating intricate components.

Types of Electrochemical Machining

ECM encompasses various specialized techniques, each tailored to meet specific manufacturing needs. Below are the primary forms of ECM:

- Electrochemical Grinding (ECG):This process combines electrochemical dissolution with mechanical grinding to efficiently remove material while reducing stress on the workpiece. ECG is particularly beneficial for machining tough materials that are challenging to process with traditional methods, offering precision without inducing heat or mechanical deformation.

- Electrochemical Drilling (ECD):ECD uses a controlled flow of electrolyte and electrical current to create precise holes by dissolving localized material. It is especially effective for producing small, deep, or intricate holes in high-strength and temperature-resistant alloys, such as those used in jet engines and turbines.

- Electrochemical Deburring:ECD removes unwanted burrs—sharp edges or protrusions—formed during other machining operations. This method is fast and precise, ensuring a clean finish without damaging the workpiece’s surface integrity.

How Does Electrochemical Machining Work?

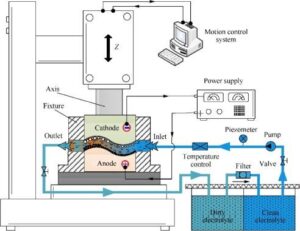

ECM relies on electrolysis, a chemical process where material is removed from the workpiece through the flow of electrical current in an electrolyte medium. Here’s a breakdown of the process:

- Electrode Configuration:

- The workpiece serves as the anode (positive electrode).

- The tool functions as the cathode (negative electrode).

- Both are connected to a direct current power source.

- Electrolyte Flow:An electrolyte solution, often sodium chloride (NaCl) or sodium nitrate (NaNO₃), flows continuously through or around the machining area to remove dissolved material and maintain the chemical reaction.

- Material Removal:As the current passes through the electrolyte, ions from the workpiece dissolve into the solution. This process is controlled to achieve the desired shape and dimensions.

- No Mechanical Contact:Unlike traditional machining, ECM avoids physical contact between the tool and workpiece. This eliminates mechanical stresses, tool wear, and heat generation, resulting in a smoother and more precise machining process.

Advantages of Electrochemical Milling

ECM offers numerous benefits that make it a preferred choice for precision machining:

- Non-Contact Machining:

- Eliminates mechanical stress and tool wear, ensuring consistent precision and durability of tooling components.

- Prevents heat distortion and thermal damage to the workpiece.

- Complex Geometries:

- Capable of machining intricate and detailed shapes with exceptional accuracy, even in hard-to-machine materials.

- Surface Finish:

- Produces smooth and refined surface finishes, often eliminating the need for secondary polishing or finishing operations.

- Material Versatility:

- Especially effective for hard, brittle materials like superalloys and composites, commonly used in aerospace and automotive industries.

- Cost Efficiency:

- Reduces long-term maintenance costs due to the absence of tool wear.

Limitations of Electrochemical Machining

While ECM is a powerful tool, it has its challenges and constraints:

- High Initial Costs:

- Equipment and setup are expensive, and the process consumes significant electrical energy.

- Material Restrictions:

- Limited to electrically conductive materials, excluding non-conductive materials like ceramics and plastics.

- Waste Management:

- The process generates waste products, including used electrolytes and dissolved metals, requiring careful disposal to avoid environmental damage.

- Tool Corrosion:

- Saline or acidic electrolytes can corrode the tool, equipment, and even the workpiece if not properly managed.

- Dimensional Accuracy Challenges:

- Overcutting, where machining exceeds desired dimensions, can occur, affecting part accuracy.

- Specialized Expertise Required:

- Operators must have a deep understanding of electrolyte properties and workpiece material behavior to maintain precision.

Applications of Electrochemical Machining

ECM is widely used across various industries for its ability to deliver precision, complexity, and quality:

- Die Sinking: Creating complex molds or cavities with high accuracy.

- Micro-Machining: Fabricating miniature components with intricate details.

- Deburring: Removing sharp edges or imperfections post-machining.

- Drilling: Producing small or deep holes with consistent accuracy.

- Surface Finishing: Refining workpiece surfaces to a smooth and polished state.

Industries Utilizing ECM

- Aerospace: Precision machining of turbine blades, fuel injectors, and structural components.

- Automotive: Crafting complex parts like cylinder heads and fuel system components.

- Medical Devices: Manufacturing surgical tools, implants, and diagnostic equipment with smooth finishes.

- Electronics: Producing micro-components for high-precision electronic devices.

- Tool and Die: Shaping molds and dies for large-scale production.

Controlling Precision in ECM

To achieve high precision in ECM, several factors must be controlled:

- Current and Voltage: Regulate to ensure a uniform material removal rate.

- Electrolyte Properties: Maintain optimal concentration and temperature for consistent conductivity.

- Interelectrode Gap: Monitor and adjust the gap to prevent dimensional inaccuracies or short circuits.

Advancements in ECM

- Electrochemical Micromachining (ECMM):Enables the fabrication of micro-features like channels, holes, and grooves with exceptional precision and surface quality.

- Pulsed Electrochemical Machining (PECM):Uses controlled pulses of direct current for enhanced precision and repeatability, with reduced risk of dimensional errors.

ECM vs. EDM

While ECM and Electrical Discharge Machining (EDM) are both non-traditional processes, they differ significantly:

- ECM: Relies on electrolysis to dissolve material. No heat is generated, making it ideal for heat-sensitive materials.

- EDM: Uses thermal energy from electrical sparks to vaporize material, often resulting in tool wear and surface roughness.

Both require electrically conductive materials and precise tooling, but ECM offers superior surface quality and eliminates thermal distortion.

ECM vs. CNC Machining

- ECM Strengths: Excels in large-scale production of intricate, precise parts. However, it is costly and unsuitable for non-conductive materials.

- CNC Machining Strengths: Highly versatile and cost-effective for both small and large-scale operations, accommodating a wide range of materials.

Each method has distinct advantages, making them complementary tools in modern manufacturing.

Contact Us:

- E-Mail: info@radonix.com

- Phone: +90 (553) 920 5500