The Brain Behind Precision Manufacturing

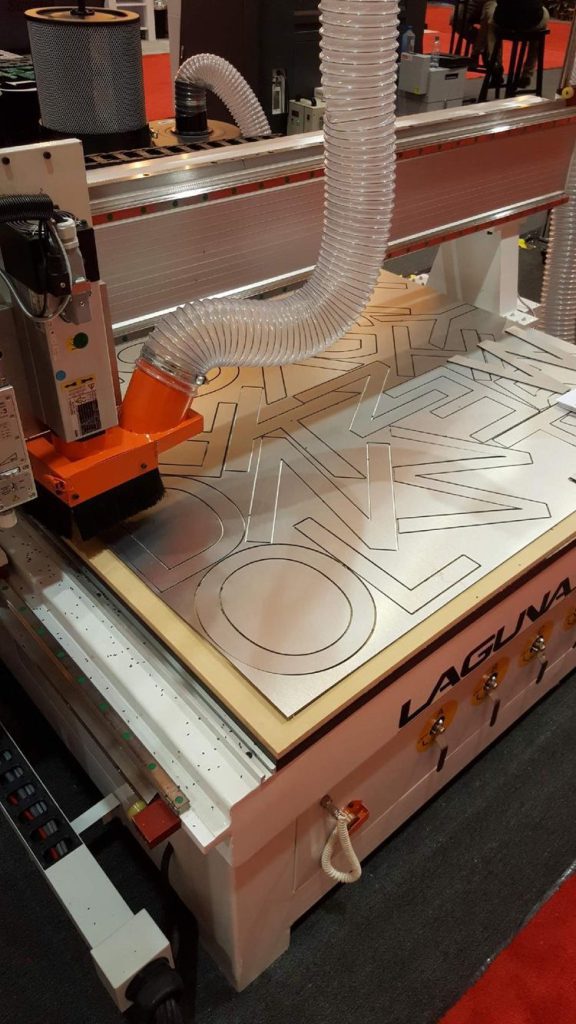

In every modern CNC (Computer Numerical Control) machine, there exists one central component that drives precision, efficiency, and coordination—the CNC controller. Acting as the brain of the system, it transforms coded instructions into real-world motion, translating every programmed line into tool paths, feed rates, and axis movements. Without it, even the most advanced machine tools would remain idle mechanical structures.

Understanding how CNC controllers work reveals the true sophistication of automated manufacturing and why choosing the right controller is crucial for achieving high accuracy, surface finish, and productivity.

The Core Role of a CNC Controller

A CNC controller performs far more than basic motion commands. It’s responsible for orchestrating every element of machine operation—from motor control and tool changes to feedback monitoring and safety supervision.

Primary Responsibilities

- Interpreting G-code: Reads and decodes every command line to execute tool paths, speeds, and spindle operations.

- Generating motion commands: Converts instructions into precise electrical signals that control each axis of movement.

- Feedback and correction: Compares actual vs. programmed positions, adjusting in real time to maintain accuracy.

- Supervising machine logic: Coordinates tool changes, coolant systems, probes, safety interlocks, and alarms.

By seamlessly integrating these functions, the CNC controller ensures that design intent from CAD/CAM programs becomes a tangible, flawless part.

How a CNC Controller Works: Step by Step

The process behind CNC control involves multiple tightly synchronized systems that translate digital input into mechanical output.

1. Program Intake

The controller receives input via G-code or manual data input (MDI) commands. This data defines every aspect of machining—feed rates, cutting depth, tool changes, and path sequences.

2. Path Planning and Interpolation

Once the program is loaded, the controller plans motion using interpolation algorithms (linear, circular, or spline). It calculates acceleration and deceleration curves while maintaining smooth transitions between moves.

3. Signal Output

Electrical signals are sent to servo or stepper drives, commanding them to move each motor in precise increments. These signals define speed, torque, and position.

4. Feedback Loop and Error Correction

Real-time feedback from encoders and sensors allows the controller to monitor accuracy. It detects even microscopic deviations and corrects them instantly—ensuring dimensional consistency.

5. Supervision and Coordination

Beyond motion, the controller oversees tool management, spindle speeds, coolant systems, and safety devices. It acts as the hub where digital logic meets physical action.

Where CNC Controllers Are Used

CNC controllers are used in a vast range of subtractive manufacturing applications, including:

- Milling for 2D/3D contouring and surface finishing.

- Turning and lathe operations for symmetrical parts and threading.

- Drilling for high-speed, multi-hole accuracy.

- Grinding and polishing for achieving fine surface finishes.

These applications depend on the controller’s ability to synchronize multiple axes and adapt to varying materials and machining conditions.

Types of CNC Controllers: Matching Performance to Need

Different machine environments call for different control architectures. Understanding the controller type ensures compatibility, scalability, and performance.

1. Stand-Alone Controllers

These are self-contained systems that integrate both hardware and user interface (HMI). Ideal for dedicated machines, they are robust and require minimal configuration.

Best for: Industrial workshops needing stable, turnkey operation.

2. PC-Based Controllers

In this setup, a PC runs specialized motion-control software that interfaces with hardware cards and drivers. These systems are flexible and customizable but require higher technical knowledge to configure.

Best for: Research, prototyping, and environments that demand software flexibility.

3. Distributed Controllers

Used in complex, multi-station setups, distributed systems coordinate several controllers over an industrial network. They handle robotics, automated lines, and synchronized cells.

Best for: Advanced manufacturing, smart factories, and Industry 4.0 integration.

Key Features and Intelligent Functions

A modern CNC controller combines mechanical precision with digital intelligence. It integrates monitoring, automation, and optimization tools that enable smarter, faster machining.

Advanced Features

- Servo and stepper motor control: Support for multi-axis coordination, dynamic speed adjustments, and torque feedback.

- Tool management: Automates tool selection, life tracking, and wear monitoring for uninterrupted production.

- Workpiece positioning: Allows 4-, 5-, and even 6-axis alignment for complex geometries.

- Auto-calibration and probing: Ensures continuous accuracy through self-check cycles.

- I/O mapping and safety control: Manages interlocks, alarms, and emergency stops for full operational safety.

- Connectivity and networking: Ethernet, USB, and wireless access for remote monitoring and diagnostics.

Why the CNC Controller Matters

Every precision component, flawless contour, and perfect cut begins with a well-tuned CNC controller. It defines the machine’s responsiveness, stability, and repeatability. Poorly configured or outdated controllers can lead to inaccuracies, extended cycle times, and premature tool wear.

The Industrial Impact

- Improved surface finishes and tolerances.

- Reduced material waste and energy consumption.

- Extended machine life through optimized acceleration control.

- Enhanced safety via intelligent monitoring systems.

In advanced industries—from aerospace and automotive to jewelry and robotics—the controller is the key determinant of both process capability and production quality.

Conclusion: The Future of CNC Control Systems

As industries embrace smart manufacturing and digital integration, CNC controllers are evolving into intelligent motion systems that learn, adapt, and self-optimize. With AI-assisted programming, cloud-based monitoring, and predictive diagnostics, the next generation of controllers will further blur the line between automation and autonomy.

At Radonix, with over 16 years of expertise in CNC controller design and industrial motion systems, we specialize in developing advanced control technologies that power precision across global manufacturing sectors. Our mission is to push the boundaries of what CNC controllers can achieve—delivering performance, reliability, and innovation in every line of code.

Contact Us:

- E-Mail: info@radonix.com

- Phone: +90 (553) 920 5500