The Latest Technological Developments and Trends in CNC Works

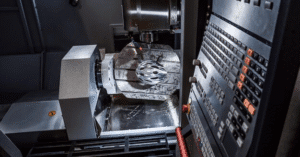

Computer Numerical Control (CNC) technology serves as the cornerstone of modern manufacturing industries. Offering high precision, repeatability, and production flexibility, CNC systems are indispensable in sectors ranging from automotive to aerospace, defense to electronics. With the rapid pace of technological advancement, CNC processes are becoming more complex, faster, and more efficient. This article delves into the prominent technological innovations and trends in the CNC Works.

Advanced Technologies in Modern CNC Control Systems

The performance of CNC machines largely depends on the capabilities of the control systems they use. While traditional CNC controllers provide basic motion coordination, modern systems enable simultaneous coordination of multi-axis movements.

Adaptive Control and Feedback Mechanisms:

Advanced control systems analyze real-time data to optimize cutting speed, depth of cut, and tool movements. Variables such as tool wear, temperature changes, or vibrations are detected and automatically adjusted by the system. This extends tool life and enhances production quality.

High-Precision Control and Multifunctionality:

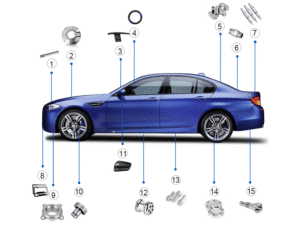

Today’s CNC machines can perform not only basic operations such as turning, milling, or drilling but also advanced tasks like complex surface machining, engraving, and multi-axis cutting on a single device. This versatility is critical for sectors such as defense and aerospace that require high-precision production.

Industry 4.0 and Digitalization

The digital transformation of CNC technology is a hallmark of Industry 4.0. CNC machines are no longer standalone units; they are now integral components of smart manufacturing ecosystems.

IoT-Integrated Systems:

Sensors and IoT-based technologies embedded in CNC machines can monitor and analyze critical information in real-time, such as machine status, production performance, and energy consumption. This enables:

- Prevention of unplanned downtime.

- Optimization of production processes.

- Enhanced energy efficiency.

Digital Twin Technology:

Creating virtual models of CNC machines facilitates the simulation of production processes. Digital twins help identify potential issues in advance, reducing production errors and costs from prototyping to mass production. This technology significantly boosts quality assurance in high-risk industries like aerospace and medical.

Robotics and Automation Systems

Robotics and automation are revolutionizing CNC machining processes. Many tasks traditionally reliant on human intervention are now fully automated.

Automated Loading and Unloading:

Robotic arms integrated into CNC machines handle tasks such as loading, unloading, and even quality control processes. This not only increases production speed but also minimizes human errors.

Cellular Manufacturing and Integration Systems:

Multiple CNC machines can be combined with centralized control systems and robotics to create cellular manufacturing systems. These systems perform multiple machining operations simultaneously, reducing costs and accelerating production processes.

Artificial Intelligence and Machine Learning

The integration of artificial intelligence (AI) and machine learning (ML) technologies into CNC operations is making manufacturing processes smarter and more autonomous.

Dynamic Process Optimization:

AI-based systems monitor CNC machine performance in real-time and automatically adjust process parameters to improve efficiency. For instance, they can detect tool wear and optimize tool change timing.

Predictive Maintenance:

Machine learning algorithms analyze historical data to predict when machines will need maintenance. This minimizes unplanned downtime and ensures production continuity.

Energy Management:

AI-driven energy optimization systems minimize the power consumption of CNC machines, enabling more sustainable manufacturing processes.

Processing Advanced Materials and Cutting Tools

CNC machines can now process not only traditional materials but also high-strength, heat-resistant advanced materials.

Challenging Materials Like Titanium and Inconel:

These materials are commonly used in aerospace and energy sectors but are difficult to machine, requiring specialized cutting tools and cooling systems.

Coated Cutting Tools:

High-performance coated tools offer longer tool life and superior surface finish. Custom-designed tool geometries ensure precise machining of challenging materials.

High-Pressure Cooling Systems:

These systems control excessive heat during machining, reducing tool wear and ensuring consistent processing.

Hybrid Manufacturing: The Convergence of CNC and Additive Manufacturing

Hybrid manufacturing systems combine additive manufacturing (3D printing) with CNC machining. These systems enable complex parts to be produced through 3D printing, followed by precision machining on CNC equipment.

Advantages:

- Material savings.

- Faster prototyping processes.

- Simplification of parts that are challenging to manufacture using conventional methods.

Hybrid systems represent a paradigm shift in manufacturing, enhancing design flexibility and providing innovative solutions.

Conclusion and Future Outlook

CNC machining technology continues to be an indispensable part of modern manufacturing. Innovations such as Industry 4.0, artificial intelligence, robotics, and hybrid manufacturing are making production processes more flexible, efficient, and sustainable.

In the future, CNC machines are expected to become more autonomous and environmentally friendly. These advancements will enhance global competitiveness and redefine the standards of industrial production.

Contact Us:

- E-Mail: info@radonix.com

- Phone: +90 (553) 920 5500