From high-precision cutting to advanced stitching functions, Radonix systems meet the diverse needs of the textile industry, ensuring efficiency, accuracy, and reliability.

Uygulama Alanları

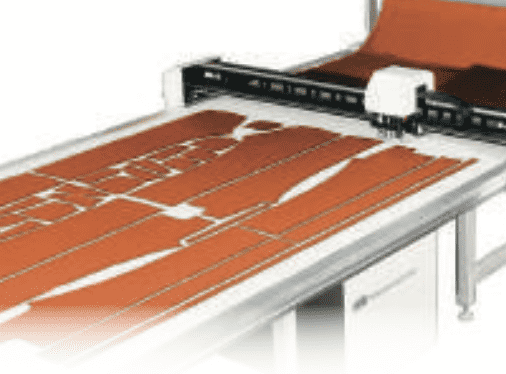

Cutting

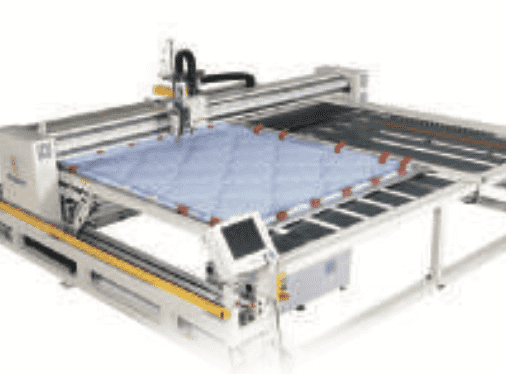

Stitching

DESCRIPTIONS

Advanced Cutting Efficiency: Control units designed to execute 2D designs with exceptional precision, supporting various textile materials and delivering clean and accurate cuts, even for the most complex patterns.

Advanced Stitching Capabilities: Radonix systems support single-axis and dual-motor sewing machines, allowing seamless processing of 2D design files in DXF format without the need for G-code. This streamlines the workflow and increases productivity.

Thread Breakage Control: The system instantly detects and intervenes in thread breakages, maintaining stitching quality through thread tension control sensors.

Customizable Stitch Options: Automatic stitch repetition at the beginning and end of the lines enhances durability and precision. Adjustable stitch spacing ensures consistent quality even with speed changes along the stitch path. Custom design sizes are automatically adjusted, making it ideal for quilting machines and other specialized applications.

High-Performance Nesting: Advanced algorithms optimize material usage by efficiently arranging parts on the fabric, minimizing waste and reducing production costs.

Parametric Workflow Support: The parametric design application quickly adapts to changes in fabric type, thickness, and intended use, providing optimal performance across different textile processes.

Automation for Quilting Machines: Specially developed features allow designs to automatically adjust to quilt sizes, ensuring consistency and high quality across different series.

Application Areas: Fabric cutting for garment production, embroidery and decorative stitching, quilting for bedding and upholstery, pattern creation, and repetitive stitching tasks.

Achieve maximum precision and efficiency in all processes from cutting to stitching with Radonix textile systems!