Metal Processing

Radonix CNC controllers and interfaces offer precision, flexibility, and efficiency for cutting, drilling, milling, punching, hammering, and many other metalworking applications.

With advanced features tailored to industry-specific requirements, our systems ensure seamless operation and optimal performance across various metalworking processes.

Uygulama Alanları

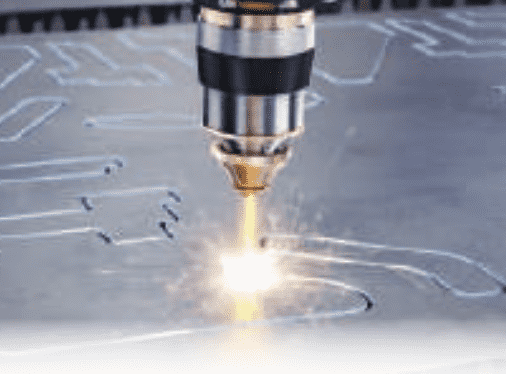

Laser Cutting

Flame Cutting

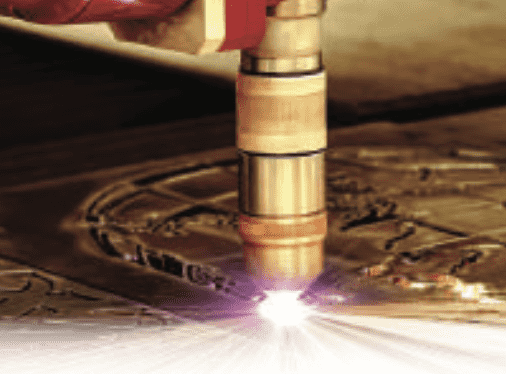

Plasma Cutting

Wire Cutting

Tube Cutting

Water Jet

Drilling

Milling

Turning

Punching

Hammering

DESCRIPTIONS

Comprehensive Cutting Support:

- Compatible with plasma, laser, flame, water jet, and tube cutting systems.

- Eliminates the need for G-code conversion by directly executing DXF files, simplifying the workflow.

- Smart Torch Height Control (THC) adapts to surface irregularities, ensuring consistent cutting quality.

- Cylindrical and flat pattern execution support, ideal for pipes and heavy metal plates.

Precision Drilling and Milling:

- XYZ interface graphically displays hole paths, offers tool management, and pre-operation simulation.

- DXF and G-code file support ensures seamless execution of various designs.

- Hydraulic compression support and smart safety alerts enhance operational reliability.

- Real-time adjustments of speed and depth provide precision in complex drilling operations.

Advanced Hammering Capabilities:

- Automatic and manual surface scanning support is essential for accurate hammering operations.

- Dual rotation mode support around the X-axis (bowl shape) and Y-axis (tray shape).

- Adjustable hammer stroke distances, overlay hammering, and partial execution of designs.

- Compatible with pneumatic and servo hammers, offering a wide range of applications.

High-Performance Punching:

- Compatible with servo, hydraulic, and pneumatic systems.

- Automatic tool-changing systems increase efficiency and reduce downtime.

- Workpiece repositioning systems allow processing of large designs exceeding table size.

- Metalix software integration offers seamless workflows from design to production.

Rotary and Tube Cutting Solutions:

- Tube cutting interfaces use rotary and linear axes to perform 360-degree precision cuts.

- Dynamic Diameter parameter adapts to changing tube sizes.

- Smart height control maintains consistent quality by preserving the distance between the torch and surface during cutting.

Laser and Profile Cutting:

- Profile Laser Cutting System provides complex 4-axis motion control for precision profile cutting.

- Advanced motion accuracy allows clean and efficient processing across various materials.

Automation Features that Increase Productivity:

- Automatic workpiece repositioning for processing large designs.

- Adaptive features like design alignment, scaling, rotation, and reflection within the software.

- Pre-set pauses before, during, and after operations simplify workflow management.

- Demo run support to test cutting outputs before activation.

Customizable Interfaces:

- Integration with various motor types, including servo, hydraulic, and crank systems.

- Real-time operational feedback with advanced visualization tools.

- Flexible parameter adjustments for cutting, drilling, and hammering processes.

Radonix metalworking solutions offer high precision, flexibility, and efficiency in production, simplifying complex processes!