Radonix CNC controllers and interfaces, designed to enhance precision and efficiency in the stone and marble industry, offer advanced functionality for complex and demanding processes. Leveraging the latest technologies, our systems support a wide range of applications such as engraving, etching, and cutting, ensuring seamless integration into both traditional and modern workflows.

Uygulama Alanları

Router

Lathe

Engraving

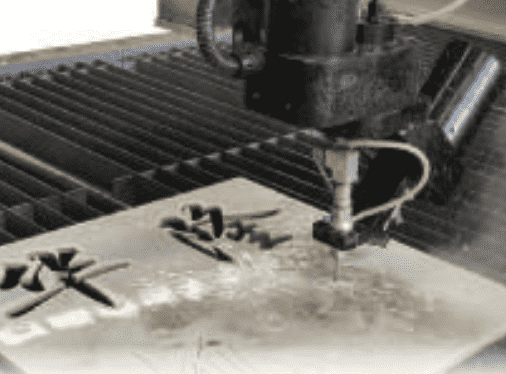

Water Jet

DESCRIPTIONS

Automatic Z-Axis Height Control: Ensures consistent and precise cuts by optimizing the distance between the nozzle and the surface, regardless of material thickness or surface irregularities.

Real-Time Adjustable Parameters: Allows operators to modify cutting speed, pressure, and abrasive flow in real-time to adapt to different material types and project requirements.

Eco-Friendly Operations: The Water Jet Interface offers a sustainable solution for industries by using water and natural abrasives, prioritizing environmental sustainability.

Enhanced Workflow Efficiency: Features such as material alignment correction and the ability to select and sort parts from large design files accelerate the production process, reducing setup time and minimizing material waste.

3D Visualization: Enables operators to preview the final workpiece in advance, enhancing accuracy in complex designs and reducing error rates.

Tool Compatibility: Supports various cutting systems and tools, including rotary and sequential tool-changing mechanisms, to accommodate different operational needs.

Parametric Adjustments: Allows operators to adjust the material removal direction forward, backward, or in both directions, optimizing surface quality by minimizing material removal in the final stage.

Advanced Safety Features: Integrated safety mechanisms enhance operator protection during high-pressure cutting processes while ensuring precise control.