Industry 4.0 in CNC Systems

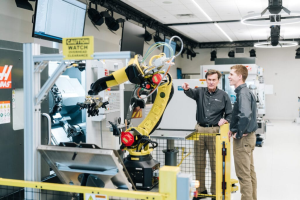

Industry 4.0 represents the digital transformation of manufacturing, uniting automation, connectivity, and data intelligence into one integrated ecosystem.

Within this transformation, CNC (Computer Numerical Control) systems play a pivotal role—serving as the foundation of precision-driven, smart factories.

Through technologies like IoT, AI, big data, robotics, and cloud computing, CNC machines have evolved from isolated tools into connected, intelligent systems that optimize themselves in real time.

This article explores how Industry 4.0 technologies are applied to CNC systems in industrial and academic settings—demonstrating how smart technologies are revolutionizing manufacturing performance, productivity, and sustainability.

1. Real-Time Monitoring and Performance Enhancement with IoT

The Internet of Things (IoT) acts as the nervous system of Industry 4.0, linking machines, sensors, and human operators in one intelligent network. In CNC systems, IoT enables continuous communication between machines, providing real-time visibility of performance and process health.

Industrial Application: IoT-Based Monitoring in the Automotive Sector

In an automotive facility, IoT-enabled CNC machines collect and transmit live data such as temperature, pressure, and vibration. This data is analyzed to optimize performance and enable predictive maintenance, reducing the risk of unplanned failures.

Results:

- 20% decrease in machine failures

- 15% improvement in production continuity

- Constant remote access for operators to monitor real-time performance

IoT-based monitoring enhances decision-making by turning every CNC machine into a source of actionable data.

Industrial Application: IoT-Based Monitoring in the Automotive Sector

An automotive manufacturing facility uses IoT sensors integrated into CNC machines to collect real-time data such as temperature, pressure, and vibration.

This data is analyzed to assess machine performance, enabling predictive maintenance and reducing the need for unplanned downtime.

With IoT-based monitoring, the failure rate of machines decreased by 20%, and production continuity was increased by 15%. Furthermore, operators can monitor machine status continuously, preventing unexpected shutdowns.

Academic Perspective: IoT Integration Research

Research highlights that IoT integration in CNC systems improves machine utilization and predictive diagnostics.

Studies confirm that real-time sensor data not only identifies issues early but also enables better maintenance scheduling and resource optimization, reinforcing IoT’s role as a key enabler of smart manufacturing.

2. Process Optimization and Predictive Maintenance with Big Data Analytics

Big data analytics processes large volumes of CNC machine data to uncover hidden patterns, trends, and inefficiencies. This insight allows manufacturers to optimize parameters such as cutting speed, feed rate, and tool life with unparalleled accuracy.

Industrial Application: Big Data in Medical Device Manufacturing

In a medical device facility, big data analytics captures information on tool wear, energy consumption, and spindle speeds. Machine learning algorithms process this data to improve efficiency and sustainability.

Results:

- 12% reduction in production costs

- 8% drop in energy consumption

- 15% increase in tool life

By combining data from hundreds of CNC machines, manufacturers achieve scalable insights that improve output quality and cost efficiency.

Academic Perspective: Data Analytics and Machine Learning

Academic studies emphasize how machine learning models analyze production data to predict tool wear and recommend optimal machining conditions. This not only enhances precision but also minimizes waste and downtime.

3. Artificial Intelligence for Process Optimization and Autonomous Control

Artificial Intelligence (AI) takes CNC automation to the next level. AI-driven systems can predict failures, correct errors, and adapt cutting parameters dynamically—creating truly autonomous production.

Industrial Application: AI in Electronics Manufacturing

In an electronics factory, AI models process temperature and vibration data to forecast tool wear. The system predicts the ideal moment for tool replacement, preventing breakdowns and reducing manual intervention.

Results:

- 30% increase in tool lifespan

- 10% improvement in production speed

AI transforms CNC systems from passive executors to self-optimizing machines capable of making real-time decisions.

Academic Perspective: Deep Learning and CNC Optimization

Academic research explores deep learning techniques to improve tool path planning, surface quality, and adaptive control. Neural networks trained on CNC operation data allow systems to self-learn optimal machining conditions, significantly improving performance consistency.

4. Cloud Computing for Remote Monitoring and Data Integration

Cloud computing centralizes CNC data, enabling remote access, performance analytics, and even automated software updates. It connects manufacturing plants globally, creating a synchronized production environment.

Industrial Application: Cloud-Based Control in Electronics Manufacturing

An electronics manufacturer uses a cloud platform to monitor CNC performance across multiple facilities. Data such as cycle time, maintenance alerts, and productivity reports are accessible from any location.

Results:

- 18% reduction in maintenance costs

- Improved cross-facility coordination

- Faster response to production issues

Cloud-based solutions also eliminate the need for on-site diagnostics, enabling maintenance teams to act proactively.

Academic Perspective: Cloud Integration in CNC Systems

Academic studies confirm that cloud-enabled CNCs streamline collaboration between engineers and operators. Shared data environments enhance traceability, version control, and continuous improvement—key components of sustainable, digital manufacturing.

5. Digital Twin Technology for Process Simulation and Virtual Optimization

The digital twin is one of the most advanced technologies in Industry 4.0. It creates a virtual replica of physical CNC machines, allowing real-time monitoring, simulation, and optimization before production even begins.

Industrial Application: Digital Twin in Aerospace Manufacturing

An aerospace company deploys digital twins of CNC machines to simulate turbine blade manufacturing. Virtual models predict potential issues, optimize tool paths, and ensure flawless part geometry.

Results:

- 12% reduction in production time

- Improved design validation before machining

- Fewer errors during live production

Digital twins bridge the gap between virtual design and physical execution—minimizing waste while maximizing precision.

Academic Perspective: Digital Twin Research and Innovation

Researchers are developing AI-enhanced digital twins capable of learning from live data to forecast future performance. These intelligent systems form the foundation of self-adaptive CNC environments, where each machine can simulate and optimize its workflow autonomously.

Conclusion: The Connected Future of CNC Manufacturing

The integration of Industry 4.0 technologies—including IoT, AI, big data, cloud computing, and digital twins—has transformed CNC systems into intelligent, networked machines.

These innovations boost efficiency, predict maintenance, and reduce operational costs, empowering industries to achieve higher precision and sustainability.

Academic research continues to expand the boundaries of what’s possible, while industrial implementation drives real-world progress. Together, they pave the way toward a future where CNC systems are not just automated—but fully intelligent, connected, and adaptive.

At Radonix, with over 16 years of expertise in CNC control systems and automation, we continue to develop technologies that merge innovation with reliability—helping manufacturers worldwide embrace the future of Industry 4.0.

Contact Us:

- E-Mail: info@radonix.com

- Phone: +90 (553) 920 5500