Hybrid Manufacturing — The Fusion of CNC and Additive Innovation

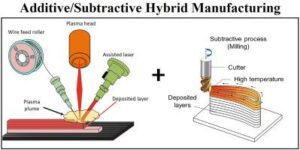

Hybrid manufacturing is redefining the landscape of modern production by merging CNC (Computer Numerical Control) precision with the flexibility of additive manufacturing. This dual-process approach enables both subtractive and additive operations on a single platform, combining the strengths of traditional machining with advanced 3D printing technologies.

By leveraging CNC’s accuracy and additive manufacturing’s design freedom, hybrid systems deliver efficiency, versatility, and innovation across industries — from aerospace to biomedical applications. This seamless integration marks a new era of smart, sustainable, and high-performance manufacturing.

Characteristics of CNC and Additive Manufacturing

CNC technology has long been the benchmark for precision manufacturing. As a subtractive process, it removes material to achieve exact shapes and tight tolerances. However, it often leads to material waste when crafting complex or hollow structures.

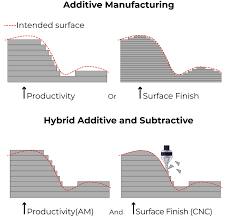

Additive manufacturing, by contrast, builds parts layer by layer. It’s ideal for producing intricate geometries while minimizing waste — though it can struggle with surface finish, strength, and dimensional accuracy.

Hybrid manufacturing merges the best of both worlds: CNC’s precision machining and additive’s creative flexibility. The result is an optimized production process capable of creating geometrically complex parts that meet industrial-grade performance and precision standards.

How Hybrid Manufacturing Works

In a hybrid manufacturing process, additive manufacturing typically forms the initial structure of a component — especially for complex, lightweight, or internal designs. Once the basic geometry is built, CNC machining refines critical surfaces, ensuring the final product meets required tolerances and finishes.

This workflow provides several advantages:

- Reduced material waste: Only the necessary material is deposited and precisely shaped.

- Optimized production time: Combining both processes on one platform eliminates multiple machine transfers.

- Improved design complexity: Enables the creation of shapes previously impossible with conventional machining alone.

By integrating these complementary techniques, hybrid manufacturing delivers both performance efficiency and design innovation.

Advantages of Hybrid Manufacturing

The most notable strength of hybrid manufacturing lies in its design flexibility and production efficiency. Complex parts — such as turbine blades in aerospace or custom prosthetics in healthcare — can be produced faster and with fewer resources.

Other major advantages include:

- Material savings: Minimizes waste by depositing material only where needed.

- Enhanced precision: CNC finishing ensures dimensional consistency.

- Broader material use: Compatible with metals, polymers, and advanced composites.

By combining speed, adaptability, and precision, hybrid manufacturing sets a new standard for advanced industrial production.

Energy Efficiency in Hybrid Systems

Energy efficiency is a defining feature of hybrid manufacturing. Since material is only added or removed as required, energy consumption drops significantly compared to traditional machining.

For instance, in aerospace component production, additive manufacturing creates a near-net shape that CNC then perfects — drastically reducing processing time and power usage.

This leaner energy profile supports both lower operational costs and sustainable production goals, making hybrid systems an eco-efficient alternative to conventional methods.

Supporting Sustainable Manufacturing

Beyond efficiency, hybrid manufacturing plays a critical role in sustainable industry transformation. By minimizing waste and optimizing energy usage, it directly contributes to environmental conservation.

For manufacturers pursuing green production certifications or carbon neutrality goals, hybrid systems offer tangible benefits — producing more with fewer resources. This approach aligns with the global movement toward sustainable industrial ecosystems, reinforcing both economic and ecological responsibility.

Challenges in Hybrid Manufacturing

While promising, hybrid manufacturing also presents several challenges. The initial investment for hybrid machines remains high, often limiting accessibility for smaller enterprises. Moreover, the integration of dual-process control systems requires advanced software and skilled operators.

Other technical considerations include:

- Material compatibility: Not all alloys or composites perform equally under both additive and subtractive conditions.

- Surface finishing: Balancing additive texture with CNC precision requires careful calibration.

- Processing speed: Multi-stage production can still face synchronization challenges.

Despite these hurdles, continuous advancements in control technology and AI-assisted automation are rapidly addressing these barriers.

The Future of Hybrid Manufacturing

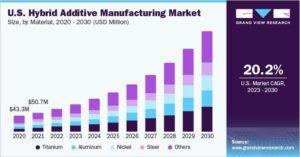

Hybrid manufacturing is gaining momentum across aerospace, automotive, biomedical, and energy sectors. Its ability to merge creative design with industrial precision makes it ideal for next-generation production.

Future trends include:

- AI-driven optimization: Real-time process adjustments through machine learning.

- Digital twin simulations: Virtual modeling to predict and refine production outcomes.

- Advanced materials: New metal alloys and composites engineered for hybrid processes.

As industries prioritize agility and sustainability, hybrid manufacturing will continue to evolve — driving faster innovation and setting new efficiency standards worldwide.

Conclusion — Radonix and the Hybrid Revolution

The combination of CNC and additive manufacturing represents a milestone in modern industrial evolution — and Radonix stands at the forefront of this hybrid revolution. By integrating both precision machining and additive capability within one intelligent platform, Radonix enables manufacturers to achieve unmatched efficiency, accuracy, and sustainability.

This transformation empowers industries to:

- Reduce material and energy waste.

- Accelerate time-to-market.

- Produce highly complex and customized parts.

As global manufacturing moves toward smarter, cleaner, and more adaptive systems, Radonix’s hybrid technology is setting the new standard for the future of production.

Contact Us:

- E-Mail: info@radonix.com

- Phone: +90 (553) 920 5500