High-Precision Part Production with CNC Lathes — The Backbone of Modern Manufacturing

CNC lathes form the foundation of high-precision manufacturing, ensuring unmatched accuracy, consistency, and efficiency. These computer-controlled machines handle complex machining tasks that meet the tightest industrial tolerances, making them indispensable in sectors like automotive, aerospace, medical devices, and energy.

By combining automation with precision engineering, CNC lathes enable manufacturers to achieve superior quality, faster turnaround times, and scalable production — all critical factors in today’s competitive industrial landscape.

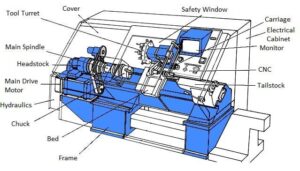

CNC Lathe Operations

CNC lathes operate using a process where the workpiece rotates while a computer-controlled cutting tool shapes it according to programmed instructions. This technique ensures consistent precision and repeatability across production cycles.

Compared to manual lathes, CNC systems deliver:

- Higher flexibility: Capable of handling complex geometries and intricate designs.

- Improved accuracy: Automated control eliminates human error.

- Faster production: Continuous operation with minimal setup changes.

This level of precision is especially valuable in industries requiring tight tolerance components, such as engines, implants, and turbine systems.

Advantages of CNC Lathes

One of the primary advantages of CNC lathes is their ability to minimize human error while maintaining consistency. Manual lathes rely on operator skill, whereas CNC systems execute programmed sequences with exact repetition.

Key benefits include:

- Precision and repeatability: Ensures identical results for large or small batches.

- Enhanced efficiency: Automated tool paths increase speed and productivity.

- Consistent quality: Reduces the risk of variation or defect across parts.

This combination of automation and precision creates a strong foundation for mass production and high-value part manufacturing.

Material Compatibility

CNC lathes can machine an extensive range of materials, from metals like steel, aluminum, and titanium to plastics and composites. Each material requires specific parameters — such as cutting speed, feed rate, and tool type — which CNC software optimizes automatically.

This adaptability allows factories to:

- Produce multi-material components efficiently.

- Switch between projects without significant reprogramming.

- Achieve consistent surface finishes across different material types.

For manufacturers serving multiple industries, this flexibility makes CNC lathes a cost-effective and versatile solution.

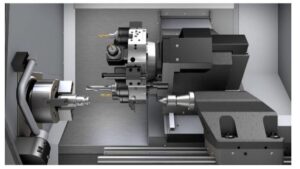

Multi-Stage Machining Capability

Modern CNC lathes can perform multiple machining operations — including turning, drilling, milling, and surface finishing — in a single setup. This eliminates manual transfers between machines and significantly reduces production time.

Advantages of multi-stage machining:

- Time savings: Multiple steps completed within one workflow.

- Improved precision: All operations share the same coordinate system.

- Lower labor costs: Reduced need for operator intervention.

This multi-functionality streamlines production, boosts accuracy, and maximizes throughput in high-demand manufacturing environments.

Maintaining Accurate Tolerances

CNC lathes excel at maintaining micron-level tolerances, a requirement in precision-critical applications. Tolerance control ensures components fit and function flawlessly within mechanical assemblies.

For example, engine parts, turbine shafts, or medical implants require tight dimensional control to perform efficiently and safely. CNC systems monitor tool wear, spindle speed, and temperature in real time — automatically compensating for any deviations.

This advanced control guarantees consistent, high-quality outputs across long production runs.

Prototyping and Rapid Iteration

CNC lathes are invaluable in prototype development, allowing designers to transform CAD models into physical parts quickly.

By translating digital designs into real components with exact dimensions, CNC lathes enable:

- Fast iteration: Engineers can test, refine, and reproduce parts within hours.

- Design validation: Early prototypes confirm functionality and performance.

- Cost efficiency: Eliminates the need for costly manual machining or external tooling.

This rapid prototyping capability accelerates innovation cycles and shortens time-to-market for new products.

Role in Industrial Production

CNC lathes play a central role in both high-volume and custom manufacturing. Their automation and repeatability make them ideal for mass production, while their programmability supports low-volume, custom parts with the same level of precision.

They enhance production by:

- Ensuring scalability: Easily adapt from one-off parts to large-scale output.

- Maintaining quality: Every piece is produced within the same parameters.

- Reducing downtime: Automated processes limit interruptions and setup times.

This adaptability gives manufacturers a strategic advantage across multiple production scales.

Efficiency Through Automation

Automation is the driving force behind CNC lathe efficiency. These machines require minimal operator input and can be integrated into smart factory systems for remote monitoring and process optimization.

Key automation benefits:

- Reduced downtime: Continuous operation with predictive maintenance.

- Improved productivity: Autonomous operation allows lights-out manufacturing.

- Data-driven insights: Sensors collect performance metrics for optimization.

Through automation, CNC lathes become intelligent systems that combine precision with operational efficiency.

Conclusion — Radonix Precision at the Core of Innovation

The role of CNC lathes in modern manufacturing extends far beyond traditional machining. They deliver precision, repeatability, and flexibility that empower industries to innovate and compete globally.

Radonix leverages cutting-edge CNC control technology to help manufacturers produce high-quality parts faster, more reliably, and at lower cost.

By integrating automation, data analytics, and precision engineering, Radonix CNC systems redefine what’s possible in high-precision part production — driving industrial excellence for the factories of the future.

Contact Us:

- E-Mail: info@radonix.com

- Phone: +90 (553) 920 5500