Imagine turning a raw aluminum block into a custom drone frame using just a few lines of code. With the right G Code Programming Examples, you can. In this 2025-ready guide, we’ll turn abstract “CNC codes” into real toolpaths that cut, drill, engrave, and contour like a pro.

You’ll get practical, step-by-step G Code Programming Examples for milling, turning, engraving, and 3D contouring, along with G-code samples you can copy, simulate, and run.

We’ll also share workflow checklists, two tables for quick reference, and modern tips like AI-assisted error-proofing.

All examples map cleanly to Radonix CNC controllers, so you can go from simulator to spindle with confidence. If you’re new to our ecosystem, start with our primer on motion and offsets on the Radonix blog: How CNC Controller Works: Full Guide to Precision Control.

For hardware that makes these G Code Programming Examples shine, see Radonix CNC controllers.

Why G Code Programming Examples Matter in Real-World CNC

Bridging theory to practice is where productivity happens. CAM tools like Fusion 360, SolidWorks CAM, and FreeCAD Path are great, but understanding and editing G-code programming Examples by hand turns you into a faster problem-solver. That flexibility pays off in prototypes, custom parts, and tight deadlines.Benefits of hands-on examples

- Faster prototyping: Spot and remove unnecessary rapids or retracts. Streamline “CNC codes” for leaner cycles.

- Better surface finish: Tune feeds, speeds, and interpolation for smoother arcs and consistent chip load.

- Lower scrap and energy use: Smart entry strategies and constant engagement reduce waste and power draw.

- Controller fluency: Recognize modal states, planes, and the differences in Fanuc G code examples vs. Haas G codes or LinuxCNC nuances.

Practical workflow

- Export from CAM, then refine with focused edits (e.g., safer clearances, improved lead-ins).

- Keep a reusable library of G Code Programming Examples and g-code samples: pockets, profiles, bolt circles, probe routines.

- Use controller-specific posts for Radonix CNC controllers and compare outputs to build intuition.

For a control-panel walkthrough and safety best practices, see: What Is a CNC Control Panel? Complete Guide 2025.

Basic G Code Programming Examples: Starting with Linear Moves

Let’s begin with a bread-and-butter operation: a straight-line cut on a mill. This is the foundation for most mill G code projects and an ideal place to practice safe starts, units, and feeds.Setup checklist

- Verify units and work offset (G21/G20, G54).

- Set plane (G17) and absolute mode (G90).

- Load tool and apply tool length (G43 H offset).

- Safe approach at clearance Z, then feed into the material.

- Exit safely and cancel modes.

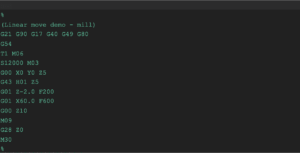

Example: Straight line cut (aluminum, 2 mm deep, 60 mm long)

Key notes

- Use G43 H01 after a tool change to activate the correct length offset.

- Keep G00 for clearances; use G01 for any cutting.

- In many Fanuc G-code examples, a safe-start block like G21 G90 G17 G40 G49 G80 is common to reset modes.

Table: Line-by-line breakdown and application

| Line | Command | Explanation | Project Application |

| 1 | G21 G90 G17 G40 G49 G80 | Metric, absolute, XY plane, cancel comp/length/cycles | Establish safe starting state |

| 2 | G54 | Use primary work offset | Aligns program zero to stock corner |

| 3 | T1 M06 | Tool 1 change | Loads end mill for facing or profiling |

| 4 | S12000 M03 | Spindle on CW at 12k | Sets cutting speed for aluminum |

| 5 | G00 X0 Y0 Z5 | Rapid to start above part | Safe approach move |

| 6 | G43 H01 Z5 | Apply tool length offset | Ensures Z depth accuracy |

| 7 | G01 Z-2.0 F200 | Feed down to depth | Controlled plunge into stock |

| 8 | G01 X60.0 F600 | Cut straight line | Edge trim or slot roughing |

| 9 | G00 Z10 | Retract to safe height | Clear stock and clamps |

| 10 | M09 / G28 Z0 / M30 | Coolant off, home Z, end | Clean exit, ready for next op |

Pro tip: Save small, well-commented G Code Programming Examples like this as templates for future mill G code projects.

Intermediate G Code Programming Examples: Arcs and Circles for CNC Projects

Arcs unlock smoother toolpaths and clean internal corners. Below are two G-code samples: a circular pocket on a mill and a fillet arc on a lathe (CNC lathe programming).

We’ll also cover “CNC scripting tips” that prevent common arc errors.

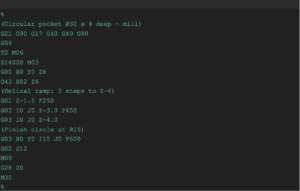

Project A: Circular pocket (Ø30 mm, depth 4 mm) with helical ramp numbered workflow

- Start above center with safe Z.

- Helical ramp to depth using CCW arcs (G03) with I/J center mode.

- Finish with a circular pass at the final radius.

- Retract to a safe height.

CNC scripting tips

- Confirm plane (G17) and I/J relative center format.

- If your post uses R instead of I/J, be mindful of quadrant rules.

- Maintain a modest step-down per revolution to avoid chatter.

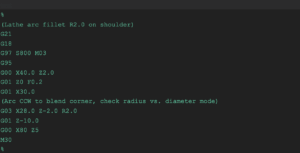

Project B: Lathe fillet arc (blend a 2 mm radius on a shoulder). We’ll use G18 (XZ plane) and a simple arc to round an external corner. This illustrates CNC lathe programming basics for arcs.

Notes

- Many lathes cut in diameter mode (X shows diameter). Verify your control setting.

- If using Haas G codes or Fanuc G code examples, arc semantics are similar, but canned-cycle details vary by control.

Why these G Code Programming Examples work

- The helical pocket reduces tool load and energy while keeping chips under control.

- The turning arc yields a neat fillet with minimal code—one of those G-code samples you’ll reuse often.

Advanced G Code Programming Examples: 3D Contouring and Engraving

Ready to level up? These advanced G-code projects show how to engrave a logo and surface a shallow 3D contour. We’ll use subroutines, variables, and loops—features common on Fanuc-style controls and supported by many Radonix CNC controllers.

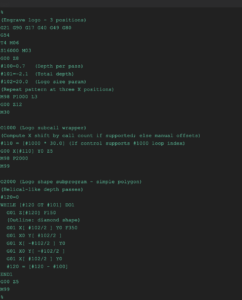

Project C: Engraving a simple logo (outline shape, repeated at 3 locations). This real-world project engraves a polygonal “logo” shape and repeats it along a plate. We use a subprogram with variables for size and depth, making it easy to scale.

Troubleshooting tips

- If your control doesn’t support macro variables or loop indices, duplicate calls with explicit coordinates.

- Use a fine-point V-bit or 1/16” ball end mill; adjust #100 to control step-down and avoid burning on wood.

- Always “air cut” engraving G Code Programming Examples first to confirm logo size and orientation.

Table: Variable parameters for Project C

| Parameter | Purpose | Typical Range | Notes |

| #100 | Depth per pass | 0.2–1.0 mm | Smaller for hardwoods and small bits |

| #101 | Final depth | -1.0 to -3.0 mm | Negative values for Z cutting depth |

| #102 | Logo size | 10–50 mm | Scales the polygon equally |

| Feed (F) | Engrave speed | 200–600 mm/min | Tune for the material and tool diameter |

| Spindle (S) | RPM | 10k–20k | Wood/plastic typically has high RPM |

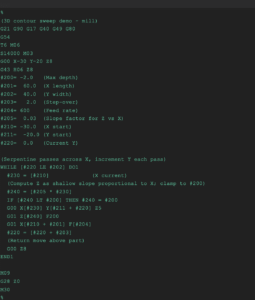

Project D: 3D contouring pass (shallow surface with parametric sweep). This example machines a gentle 3D slope using a series of parallel passes. It’s the essence of many advanced G-code projects for surfacing molds or ergonomic forms.

Why this works

- Simple math links X to Z for a smooth slope; tightening stepover #203 improves finish.

- Swap in a ball end mill and lower feed for better scallops.

- These G Code Programming Examples are great for quick prototypes before running full CAM surfacing.

If you need controller-safe posts and macros, check Radonix CNC controllers and the Radonix CNC Control Board.

2025 Innovations: AI-Enhanced G Code for Sustainable Projects

AI-assisted workflows are now standard for many small shops. You can prompt an AI assistant to draft G-code programming Examples, generate G-code samples from sketches, or review code for modal conflicts. Paired with a good simulator, this accelerates iteration. Sustainability and error-proofing

- Optimize non-cutting motion: Consolidate retracts, use efficient lead-ins, and reduce air moves. “CNC codes” that minimize rapids save both time and energy.

- Constant engagement: Trochoidal or adaptive patterns keep tool load stable and lower power peaks.

- Automated checks: AI can scan for unit/plane mismatches and missing cancels—valuable for advanced g-code projects where complexity rises.

Radonix integrations

- Radonix CNC controllers work with mainstream CAM posts and support modern macro features used in these G Code Programming Examples.

- Explore controller selection, I/O, and motion planning on Radonix CNC controllers and read our blog insights on AI in programming and verification to keep your workflow future-ready.

More Realistic Project Playbook: From Prototype to Production

Use these G Code Programming Examples as building blocks across project types. Prototyping

- Start with conservative feeds and clear annotations.

- Keep short programs and rely on G54–G59 to run multiple part zeros on one stock.

- Maintain a library of g-code samples like “bolt circle,” “pocket + bore,” and “engrave serial” for quick turnarounds.

Custom parts

- Parameterize depth, stepover, and size with macro variables to serve multiple SKUs with one program.

- For CNC lathe programming, standardize threading and grooving cycles into callable subs.

Production runs

- Add probing routines to verify stock and adjust wear offsets automatically.

- Log runtime data and tool life; tie into shop dashboards via controller I/O.

For deeper controller behavior, read: Types of Controllers in CNC Machines Explained and How CNC Controller Works: Full Guide to Precision Control.

Conclusion: Put These Programs to Work

You’ve seen how targeted G Code Programming Examples can drive real results—faster prototypes, cleaner finishes, and fewer mistakes. Start with linear cuts, build confidence with arcs and pockets, then push into engraving and 3D contouring.

Keep a personal library of G-code samples and refine them over time. Whether you use Fanuc G code examples, Haas G codes, or open-source interpreters, the fundamentals transfer.

Want seamless execution? Pair these G Code Programming Examples with Radonix CNC controllers for smooth motion, crisp HMIs, and robust macro support. Download and adapt the examples above, then iterate for your materials and tooling

Test these G code programming examples on Radonix hardware—shop now at radonix.com

FAQ

Q1: How do I simulate G Code Programming Examples before cutting?

A: Use a trusted simulator (CAM verify, LinuxCNC preview, or third-party tools). Check units, work offsets, and planes first. Watch for rapids near fixtures, verify arc centers (I/J vs. R), and run an air cut above the part to validate the path on your machine.

Q2: What’s the safest “startup block” for milling projects?

A: A common pattern is G21 G90 G17 G40 G49 G80 followed by your work offset (G54), tool change, spindle on, and G43 Hxx to apply tool length. This clears modal states and prepares a predictable baseline for any G Code Programming Examples you load.

Q3: Where can I find differences between Fanuc G code examples and Haas G codes?

A: Controller manuals are best. See Haas’ knowledge base and Fanuc references; nuances include canned cycle formats, macro availability, and parameter behavior. Always validate post-processor settings and test with small, low-risk parts first.

Q4: How do I adapt g-code samples from metric to inch?

A: Set G20 for inch or G21 for metric and adjust all coordinates, feeds, and spindle speeds accordingly. Be consistent—don’t mix inch units with metric feeds. Many shops keep separate libraries of G Code Programming Examples by unit system.

Q5: What’s a quick checklist to avoid arc errors?

A: Confirm plane (G17/G18/G19), use correct center mode (I/J vs. R), and ensure the end point lies exactly on the arc. Tiny rounding issues can break arcs; if needed, use linearized segments from CAM. This is crucial in advanced g-code projects.

Q6: Do Radonix CNC controllers support macros and subprograms?

A: Yes, Radonix CNC controllers support common macro features and subprogram calls used in the examples. Verify your firmware’s macro options and memory limits, and store reusable subroutines for pockets, engraving, and 3D sweeps.

Contact Us:

- E-Mail: info@radonix.com

- Phone: +90 (553) 920 5500