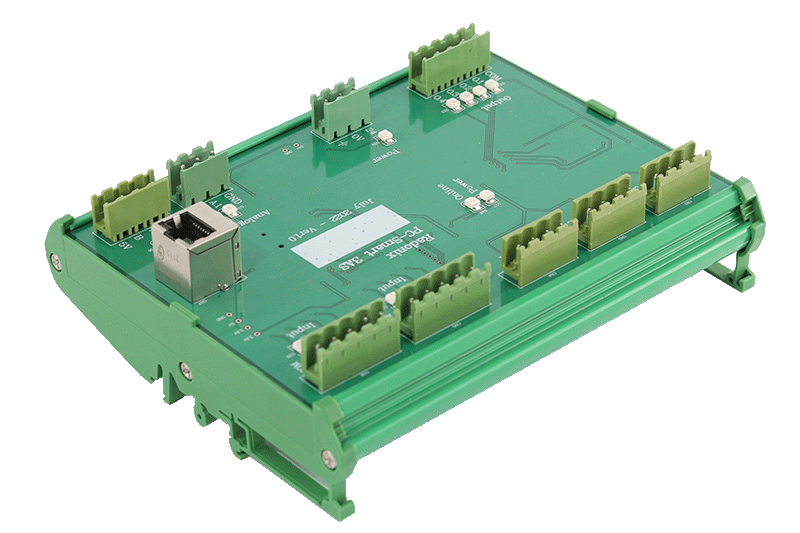

3 Axis

PC Smart 3AS

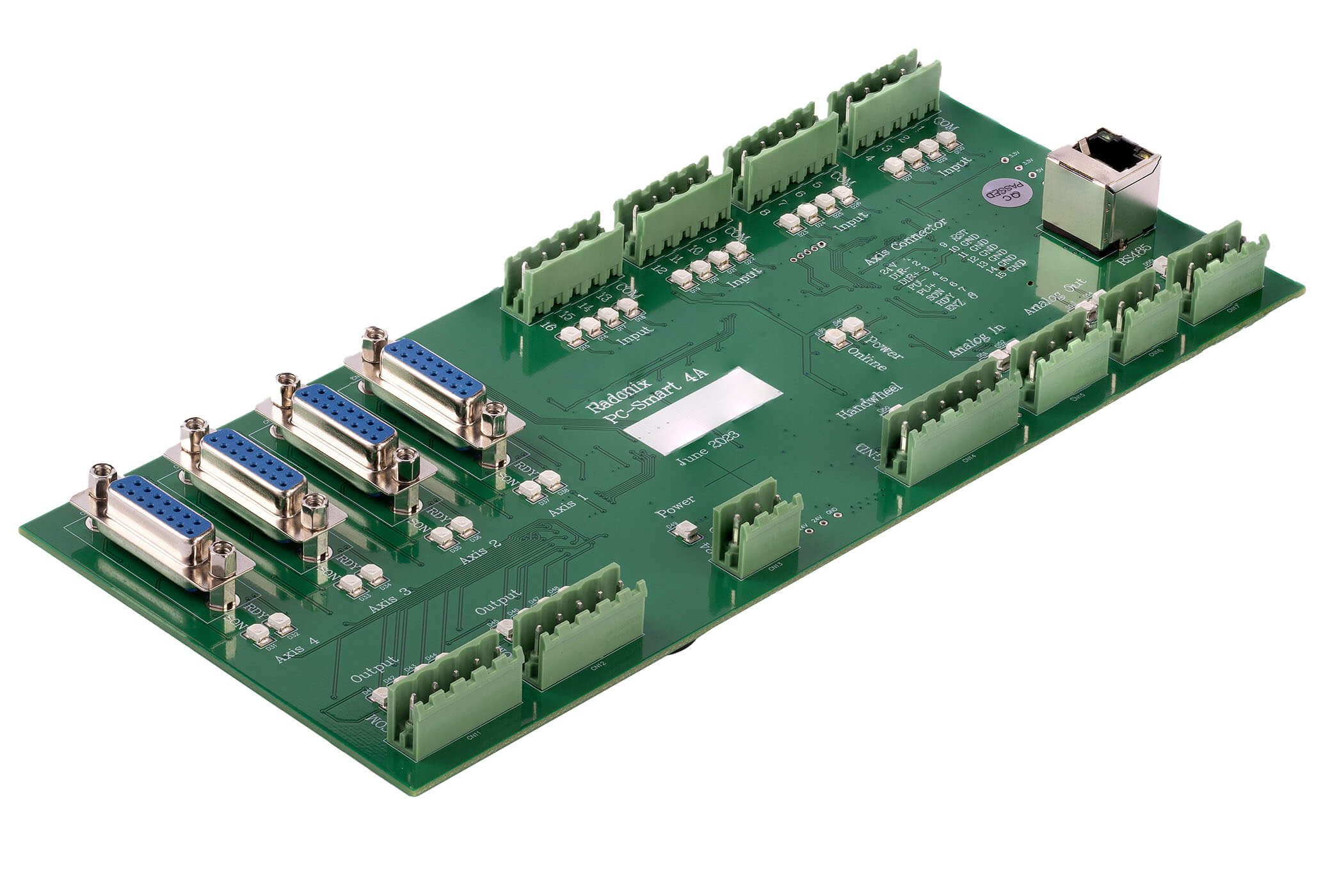

4 Axis

PC Smart 4A

6 Axis

PC Smart 6A

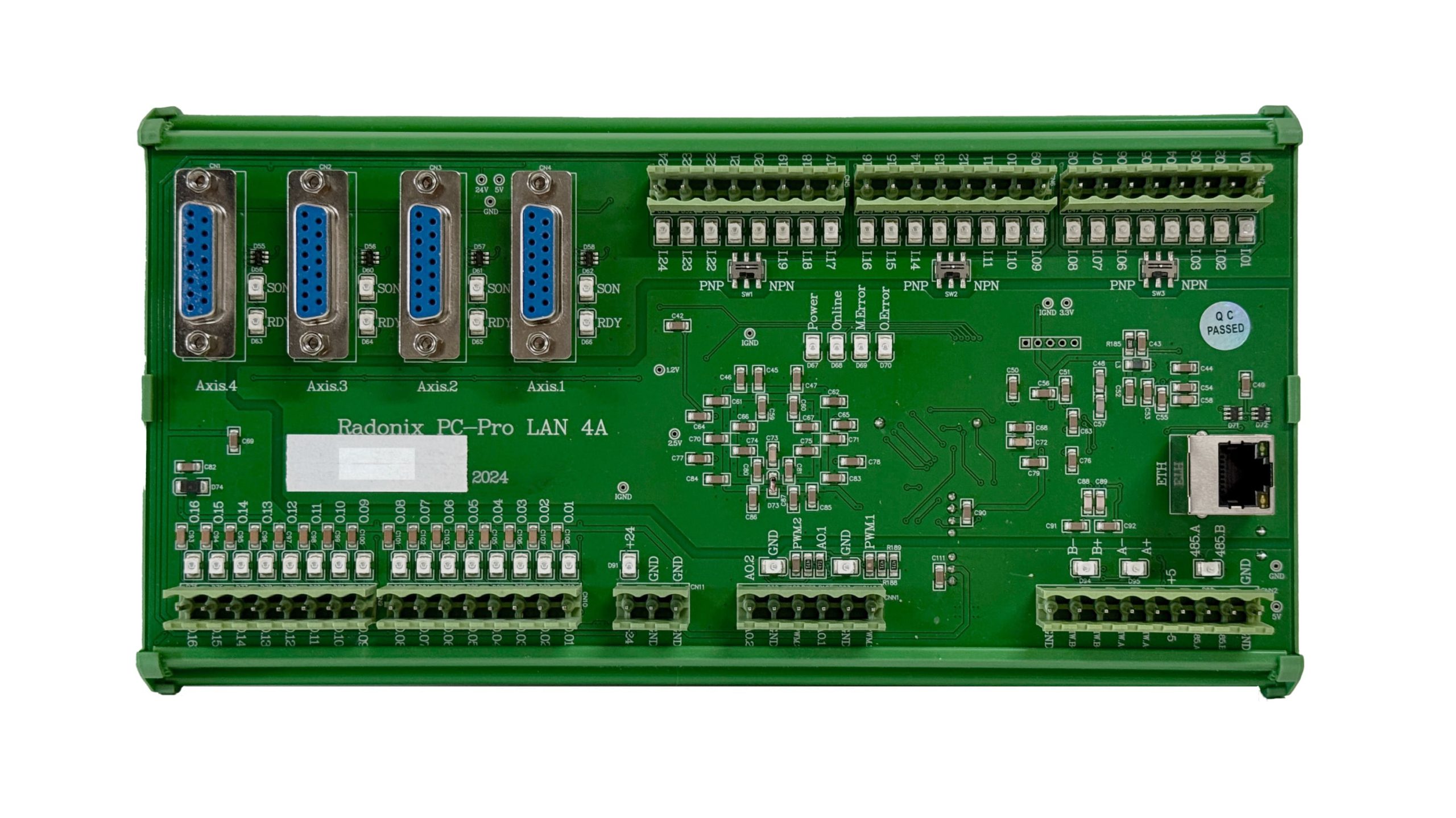

4 Axis

PC-Pro LAN 4A

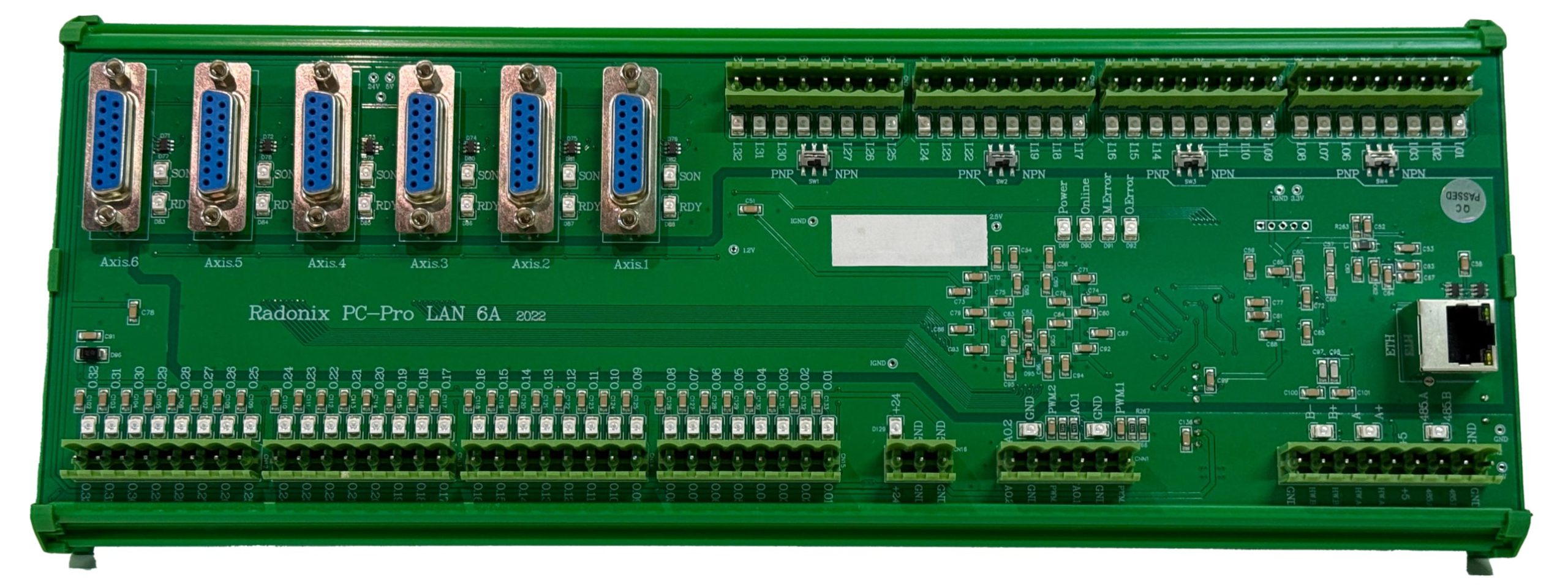

6 Axis

PC-Pro LAN 6A

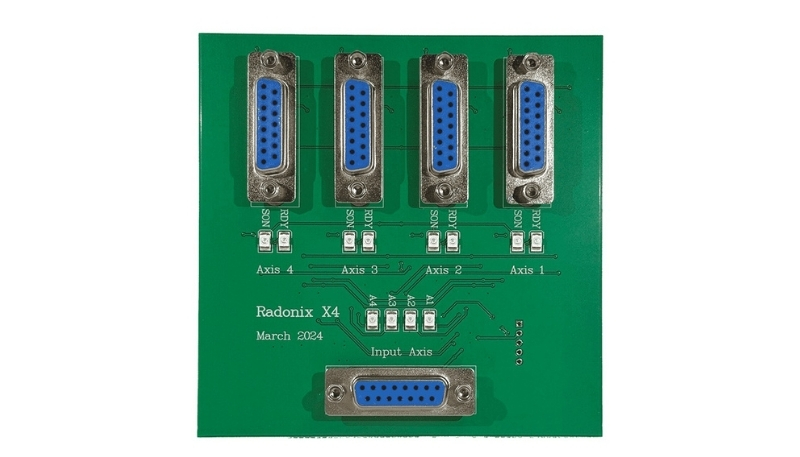

Axis Expender

Radonix X4 Expander

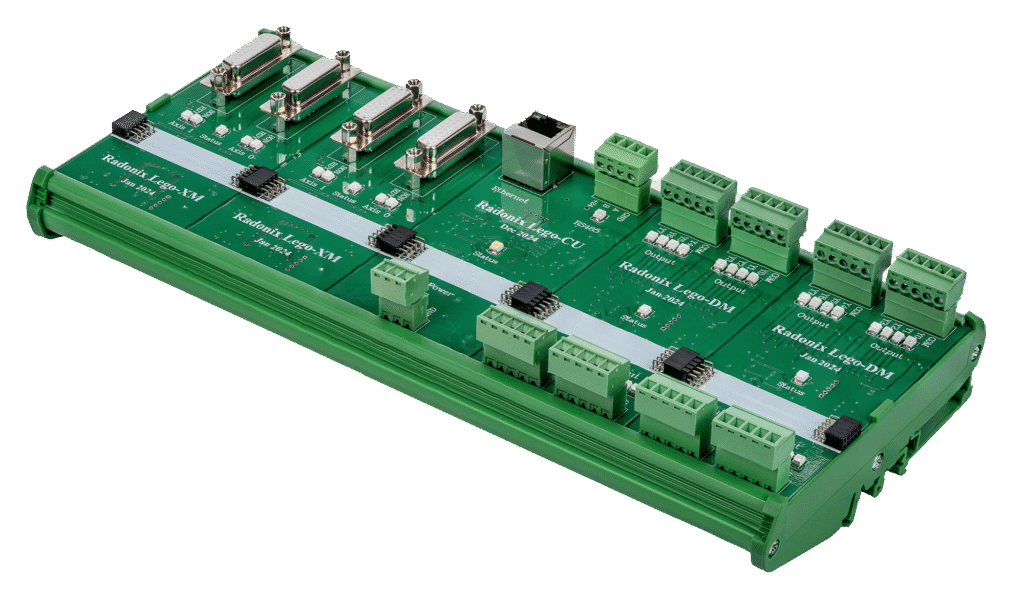

16 Axis

Radonix Lego

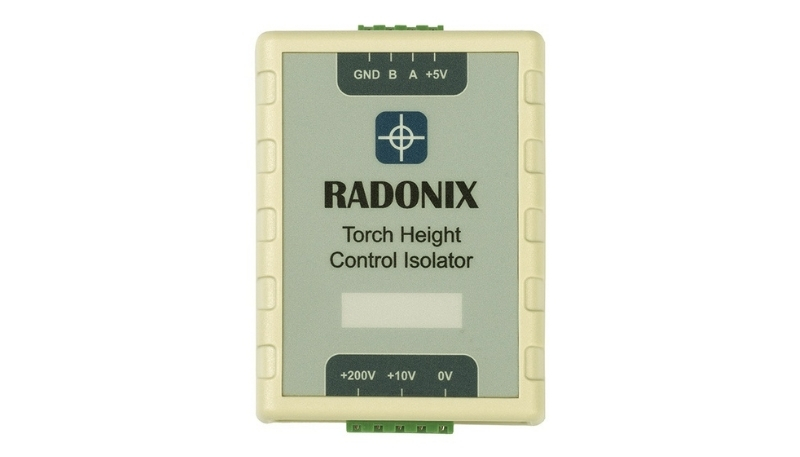

Automatic Torch Height Controller

Radonix Torch Height Controller (THC)

Radonix Handwheel

IPC Package

CNC Control Card – Global Leading CNC Control Cards & Industrial Automation Solutions

Why Radonix is the Global Leader

- Cutting-edge innovation in CNC control technology

- Comprehensive and constantly evolving product portfolio (PC Pro LAN & PC SMART series)

- Customer-focused support and services worldwide

- Proven reliability for small workshops to large-scale industrial enterprises

- Long-lasting, future-proof solutions that grow with your business

Industry-Specific Solutions

- Stone & Marble CNC: Perfect for router, lathe, engraving, and waterjet machines

- Wood CNC: Maximum efficiency in furniture, door, window, turning, engraving, and sawing

- Metal CNC Machines: Ideal for milling, turning, laser, plasma, waterjet, wire cut, and pipe cutting

- Glass & Ceramic CNC: Clean and precise cutting, engraving, and waterjet operations

- Textile CNC Machines: Optimized cutting, sewing, and pattern processing

- Plastic & Composite CNC: Superior performance in hot wire cutting, molding, and pipe processing

- Foam Injection & Jewelry CNC: High productivity and finest detail in foam molding and jewelry production

Discover the full range of Radonix CNC control cards and industrial automation hardware today. Experience tomorrow’s manufacturing technology with unmatched precision, efficiency, and reliability – choose Radonix.

Why Choose Our CNC Control Cards?

High Performance & Precision

- Optimized hardware solutions that maximize CNC machine performance

- Delivers exceptional accuracy and ultra-precise motion control

- High-speed pulse output with advanced motion profiles

- Minimizes production errors even in the most demanding applications

Wide Range of Applications

- Fully compatible with CNC machines across multiple industries:

- Stone & Marble

- Woodworking

- Metal processing

- Glass & Ceramics

- Textiles

- Plastics & Composites

- Foam injection

- Jewelry manufacturing

Industrial Automation & Maximum Efficiency

- Significantly increases productivity

- Reduces operational and maintenance costs

- Creates faster, smarter and more efficient production lines

- Seamless integration with both servo motor and stepper motor systems

Advanced Connectivity & User-Friendly Interface

- Multiple digital and analog I/O ports

- Encoder zero position input

- Relay outputs for fast homing

- Relay outputs for external device control

- Intuitive and easy-to-use operator interface

- Simplifies machine setup and daily operation