Digital Twin Technology and CNC Systems: Industrial Applications and Future Perspectives

Digital twin technology is a digital modeling approach aimed at creating a virtual replica of physical objects, machines, or systems.

This technology is considered one of the key components of Industry 4.0. The integration of digital twins in CNC (Computer Numerical Control) systems plays a revolutionary role in optimizing production processes, improving maintenance operations, and providing innovative solutions during the design phase.

The use of digital twins, supported by real-time data, allows for a more accurate analysis of machine performance and enables proactive improvements.

This article will discuss the role of digital twin technology in CNC systems, its industrial benefits, and potential future applications.

Use of Digital Twins in CNC Systems

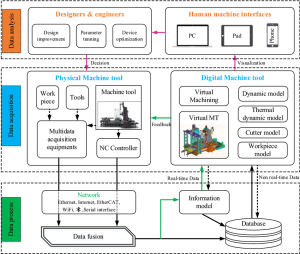

To enhance the efficiency of CNC machines and optimize production processes, digital twins create virtual representations of the machines and continuously update them with real-time data. This allows for a better understanding of machine processes, monitoring of performance, and implementation of various improvement strategies.

1. Real-Time Monitoring and Performance Analysis

Digital twins enable real-time monitoring of CNC machines in a virtual environment. Machine parameters such as operating conditions, speed, temperature, and vibration are transferred to the digital twin. As a result, the current status of machines can be observed in the virtual environment, and potential failures can be predicted in advance. Operators and maintenance teams can intervene more quickly, minimize downtime, and improve machine efficiency using these data.

2. Proactive Maintenance and Failure Prediction

Digital twins track each component of CNC machines, allowing for the prediction of maintenance needs and failure risks. Continuously updated digital twins based on data from the machines can make failure predictions based on past performance analysis. This helps extend the lifespan of machines and ensures more efficient planned maintenance. Unexpected downtimes and production losses are minimized, reducing production costs.

3. Design Process and Simulation Improvements

Digital twin technology also plays an important role in the design phases of CNC machines. Digital twins of new machines and systems can be created to conduct virtual tests during the design process. These virtual tests help detect design errors early on, avoiding costly mistakes in prototype production. Furthermore, various production scenarios can be simulated to determine the most efficient operational parameters. This provides a significant advantage in optimizing the design and improving the production process.

Industrial Benefits and Applications

The integration of digital twin technology in CNC systems offers several significant industrial advantages. These benefits contribute to improving both machine performance and overall production efficiency.

1. Increased Efficiency and Process Optimization

Thanks to digital twins, the performance of CNC machines can be continuously monitored, and processes can be made more efficient. Real-time data analysis and simulations optimize machine operating conditions and minimize delays in production processes. This results in faster production, lower costs, and high-quality products.

2. Sustainable Production and Resource Management

Digital twins offer opportunities for sustainable production by monitoring environmental factors such as energy consumption and material usage. CNC machines’ energy efficiency can be optimized, preventing unnecessary energy consumption. Additionally, digital twins help minimize material waste during part production, reducing environmental impacts.

3. Flexibility and Customized Production

Digital twins allow for the testing of different production scenarios, enabling CNC machines to work more flexibly. As a result, production processes can be quickly adapted and customized. This flexibility enables rapid adjustment for low-volume productions or customized products, allowing for quicker responses to customer demands and more agile production.

Future of Digital Twins and CNC Technologies

The future use of digital twin technology in CNC machines will continue to expand. The integration of IoT (Internet of Things) and artificial intelligence will enhance the analysis and control capabilities of digital twins. In particular, integration with robots and autonomous machines used in production lines will lead to the creation of fully automated and unmanned production lines.

Advancing digital twin technologies will enable the continuous improvement of CNC machines even under unpredictable conditions. Additionally, virtual reality (VR) and augmented reality (AR) applications will allow operators to manage machines more efficiently. In the future, digital twins will possess greater autonomy at every stage of the production process and will revolutionize industrial manufacturing processes.

Conclusion

Digital twin technology holds significant potential to improve the efficiency of CNC machines, optimize maintenance operations, and make production processes more flexible.

Real-time data analysis, proactive maintenance, and design improvements offer key industrial advantages.

The integration of digital twins in CNC machines will make future production systems more efficient, sustainable, and competitive.

This technology, as a fundamental element of Industry 4.0 and 5.0, will continue to drive innovation in the manufacturing world.

Contact Us:

- E-Mail: info@radonix.com

- Phone: +90 (553) 920 5500