Digital Twin Technology in CNC Machining: Virtual Precision for Real-World Performance

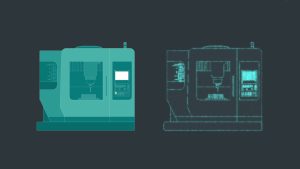

Digital Twin Technology is revolutionizing how CNC machining systems are designed, monitored, and optimized.

By creating a dynamic virtual replica of physical machines, manufacturers can simulate operations, test outcomes, and predict performance before actual production begins.

This powerful innovation bridges the gap between theory and execution, improving efficiency, precision, and predictive control across modern manufacturing environments.

1. Virtual Simulations for Error Reduction

Digital Twins enable engineers to test machining processes in a fully virtual environment. Tool paths, spindle speeds, feed rates, and cutting parameters can be simulated and optimized before real-world implementation. This process:

- Reduces material waste by minimizing trial-and-error experimentation.

- Shortens setup times and production cycles.

- Ensures accuracy from the first production run.

For example, aerospace manufacturers use Digital Twins to simulate cutting titanium components, identifying optimal tool angles and speeds before machining begins—saving both time and resources.

2. Real-Time Monitoring and Predictive Analysis

Connected IoT sensors continuously stream live data from CNC machines into their virtual counterparts. This allows engineers to monitor real-time performance and compare it to digital benchmarks. Key benefits include:

- Continuous Performance Tracking: Identify deviations in spindle load, vibration, or temperature instantly.

- Predictive Maintenance: Detect early signs of tool wear or mechanical faults to prevent costly downtime.

- Proactive Adjustments: Adapt machining parameters in real time to maintain consistency and precision.

By merging live data with simulation, manufacturers gain predictive insights that optimize production and extend machine lifespan.

3. Streamlined Setup and Operator Training

Digital Twins provide a safe, risk-free environment for operator training and setup testing. New operators can practice workflows virtually, building familiarity with machine interfaces and procedures without the risk of damaging equipment. Additionally, new production setups can be digitally tested and validated before execution—reducing human errors and onboarding time.

4. Remote Collaboration and Industry 4.0 Integration

Digital Twin systems integrate seamlessly with Industry 4.0 technologies such as IoT, AI, and cloud computing. This allows engineers and teams to collaborate remotely in real-time, analyzing and optimizing the same virtual model from different locations. Remote access capabilities enable global teams to:

- Share live performance data securely.

- Run simulations collaboratively.

- Make design and process adjustments instantly.

This connectivity supports smart manufacturing ecosystems where digital communication replaces manual intervention.

5. Process Optimization and Continuous Improvement

Digital Twins enable continuous improvement by collecting and analyzing large volumes of process data over time. Through advanced analytics, manufacturers can:

- Identify production bottlenecks.

- Enhance toolpath efficiency.

- Optimize cycle times for higher throughput.

Every data point contributes to fine-tuning performance, ensuring that manufacturing lines evolve alongside new demands and innovations.

6. Quality Assurance and Traceability

In industries where precision is paramount, such as aerospace, medical, and automotive manufacturing, Digital Twins elevate quality control. Each machining parameter and adjustment is digitally recorded, creating a transparent record of the entire production process. This digital traceability allows for:

- Easy validation of quality standards and certifications.

- Rapid root-cause analysis of defects.

- Improved compliance with industry regulations.

This level of accountability not only strengthens brand trust but also improves long-term operational reliability.

7. Future Outlook: The Power of Predictive and Autonomous Manufacturing

The adoption of Digital Twin Technology represents a major step toward predictive and autonomous CNC operations. As AI and machine learning continue to advance, Digital Twins will evolve from reactive tools to intelligent systems capable of self-optimization. Manufacturers will soon experience:

- Fully autonomous machining processes.

- Real-time optimization based on live data and predictive analytics.

- Seamless integration with 5G and edge computing for ultra-fast data exchange.

These advancements will redefine productivity, sustainability, and competitiveness in global manufacturing.

Conclusion

Digital Twin Technology is no longer a futuristic concept—it is an essential tool for next-generation CNC machining. By merging the digital and physical worlds, manufacturers can achieve virtual precision that directly translates into real-world performance. The result: greater efficiency, higher quality, and predictive capabilities that keep production running at peak performance.

Radonix Expertise in CNC Control

With over 16 years of experience in advanced CNC system design, Radonix stands as a leader in industrial automation across the Middle East and beyond. Our innovative CNC controllers empower manufacturers to harness technologies like Digital Twin, AI, and IoT to achieve smarter, more efficient, and future-ready machining environments.

Contact Us:

- E-Mail: info@radonix.com

- Phone: +90 (553) 920 5500