In 2025, a flawed HMI can spike operator errors by 30% and drag productivity across entire shifts.

If your team builds or specifies interfaces for CNCs, presses, robots, or hybrid cells, this guide is for you. We’ll unpack HMI Design for Manufactured Devices with a strong CNC lens—bringing together user-centered design, responsive layouts, and deep integration with the CNC machine control unit and PLC.

You’ll get a practical process (research → prototyping → testing), best-practice wireframes, tool suggestions (Figma, Qt), and examples of Radonix HMI-integrated CNC controllers in action.

We’ll also cover accessibility and ergonomic HMI design for harsh environments, 2025 advances like adaptive AI interfaces and voice/gesture control, and how sustainable choices reduce fatigue and injuries. For control-layer context, skim our primer: How CNC Controller Works: Full Guide to Precision Control on the Radonix blog.

Key Principles in HMI Design for CNC Control Panels

HMI Design for Manufactured Devices must reflect how people actually work—under time pressure, with gloves, around noise, and across shifts. Getting this right for CNCs means mapping operator intent to safe, efficient controls and feedback.

Core fundamentals

- User research and task mapping

- Interview operators, setup techs, and maintenance. Shadow real jobs, note pain points, and prioritize frequently used tasks. This evidence anchors HMI Design for Manufactured Devices to actual workflows in industrial cnc control systems.

- Accessibility and ergonomics

- Follow ISO 9241 for visual ergonomics and ISO 11064 for control center layouts. Ensure large touch targets, glove-friendly gestures, and readable type at distance and glare angles.

- Visual hierarchy

- Make the most important information the largest and closest: cycle state, alarms, feed/spindle overrides, and WCS/tool indicators.

- Feedback loops

- Every action needs immediate, multisensory confirmation (visual, audio, optional haptic). Live status of interlocks and machine states reduces uncertainty.

- Consistency and predictability

- Place CNC essentials (Program, Offsets, Alarms, I/O, Jog) in consistent locations. Standardize icons, colors, and navigation.

- Resilience

- Offline-first data caching, watchdog timers, and safe defaults if the network drops—critical in connected cells.

Tailoring HMI Design for CNC Machine Control Units

The HMI CNC control panel is more than a pretty screen; it’s the operator’s lens into motion, safety, and quality. Aligning HMI Design for Manufactured Devices with CNC kernel and PLC behavior ensures real-time insight and predictable responses.

What the CNC focus adds:

- Real-time data visualization

- Show the following error, axis states, spindle load, temperature, and interlocks. For each alarm, expose likely causes and a guided fix flow. This tight coupling with the CNC machine control unit increases trust.

- Alarm prioritization and context

- Differentiate Warning vs. Fault vs. Safety stop. Capture context (active tool, WCS, overrides) when faults occur to speed recovery.

- Safe macro actions

- One-tap “Safe Retract,” “Probe Corner,” or “Resume @ Reduced Feed,” with confirmation prompts and role checks.

- Performance overview

- Per-part cycle time, tool wear estimates, and energy-per-part to support continuous improvement.

Table: Design elements aligned to the CNC application and benefit

| Design Element | CNC Application | Benefit |

| Always-on modal bar | Units, WCS, plane, tool, overrides | Prevents wrong-mode errors at a glance |

| Alarm center with guided steps | Fault diagnosis mapped to I/O states | Faster, safer recovery; less guesswork |

| Live axis scopes | Following error, position, velocity | Quicker tuning and chatter troubleshooting |

| Role-based dashboards | Operator vs. Setup vs. Maintenance | Less clutter; shorter training time |

| Soft + hard-key redundancy | Cycle start/hold, E-stop, jog | Glove reliability; safe reflexes |

| Offline cache + sync | Remote facilities/spotty Wi‑Fi | Keeps work moving during outages |

| Contextual help | Tap-to-explain cycles, offsets, M-codes | Just-in-time learning on the floor |

| Dark/bright themes | Changing light and glare | Lower eye strain; fewer mis-taps |

Why does this matter to the CNC machine control unit

- The CNC kernel runs deterministic loops; the HMI should not block safety or control. Architect async updates so HMI remains snappy while the control unit stays real-time.

- Many industrial CNC control systems expose diagnostics via a fieldbus (EtherCAT/Profinet). Mirror this in dashboards, not buried menus.

For deeper panel mechanics and layout options, see: What Is a CNC Control Panel? Complete Guide 2025 on the Radonix blog.

Step-by-Step HMI Prototyping for CNC Control Panel Functions

A repeatable design process turns ideas into robust CNC HMIs quickly. Below is a field-tested flow anchored in HMI Design for Manufactured Devices, with CNC-specific examples.

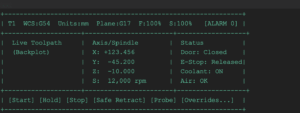

- Wireframing basics (low fidelity)

- Goals: Information architecture and task flows. Use Figma to sketch screen groups: Run, Program, Offsets, Alarms, I/O, Jog.

- Include CNC essentials early: WCS/tool bars, status strip (door, E-stop, coolant), and CNC control panel functions like jog increments and axis selectors.

- Interactive mockups (mid fidelity)

- Link screens with transitions. Prototype soft-key menus, alarm drilldowns, and “safe resume” confirmation.

- Bring data realism: sample feeds/spindle, axis readouts, and typical alarm messages.

- Usability testing (on-site if possible)

- Recruit operators from all shifts. Test common tasks: load program, set G54, run single-block, clear a fault, probe a corner.

- Collect time-on-task, error counts, and subjective ratings. Iterate weekly.

- High-fidelity prototyping and embedded preview

- Translate to Qt/QML for responsive embedded HMI, or web-based frameworks with hardened browsers. Connect a dev controller to replay real CNC telemetry.

- Pilot deployment

- Install on one machine or cell. Track KPIs: training time, mean time to recovery (MTTR), and first-article success rate.

ASCII wireframe sketch: CNC run screen

Case study: Radonix HMI halves training time

- Situation: A mid-sized shop struggled with mixed-brand panels; new hires took weeks to reach proficiency.

- Action: Consolidated to Radonix HMI-integrated CNC controllers and applied HMI Design for Manufactured Devices principles: role-based dashboards, always-on modal bars, and a single “safe resume” macro. Mapped recurring cnc control panel functions to prominent soft keys.

- Result: Training time dropped by ~50%; MTTR fell 35% thanks to consistent alarm flows and contextual help.

Table: Prototyping tools and where they fit

| Tool | Stage | Why it helps | Notes |

| Figma | Wireframe → Interactive mock | Rapid iteration, easy stakeholder reviews | Build a shared component library |

| Qt/QML | High-fidelity embedded HMI | Native performance, GPU-accelerated UI | Great for touchscreen HMI manufacturing |

| React/TypeScript + WebView | Cross-platform HMI | Fast dev, rich ecosystem | Harden with kiosk mode and offline cache |

| Python + PyQt | Rapid POC on dev rigs | Quick data binding to CNC simulators | Transition to C++/Qt for production |

| Radonix HMI SDK | Integration | Direct access to CNC telemetry and macros | Shortens time from mockup to machine |

Looking for controller-side integration? Explore Radonix HMI-integrated CNC controllers and the Radonix CNC Control Board for I/O expansion.

Challenges in HMI Design for Harsh Manufacturing Environments

Manufacturing floors are unforgiving. HMI Design for Manufactured Devices must handle temperature swings, fluids, dust, and variable lighting—while staying clear and responsive.

Common challenges—and how to address them

- Durability and seal integrity

- Use IP65+ enclosures, toughened anti-glare glass, and sealed e-stop and jog modules. Test with coolants and chips.

- Glove usability and accuracy

- Prefer large, high-contrast touch targets; provide hard-key redundancy for critical controls on the hmi cnc control panel.

- Multi-user access and role security

- Implement role-based access (Operator/Setup/Maintenance/Admin). Protect critical settings and macros behind PINs or NFC badges.

- Data visibility vs. noise

- Use progressive disclosure: minimal run view during cycle; expand into diagnostics only when needed. Keep “always-on” modal indicators visible.

- Offline operations and sync

- Cache logs and programs locally; confirm sync status clearly. Never block cycle start due to network delays.

- Hygiene and sustainability

- Dark themes at night reduce eye strain; anti-glare coatings reduce squinting. These choices in HMI Design for Manufactured Devices support lower fatigue and better long-shift performance.

Tie-ins to industrial cnc control systems

- Integrate fieldbus diagnostics (EtherCAT/Profinet) into dashboards for quick node health checks.

- Expose servo following error plots for tuning. This reduces support tickets and accelerates first-article signoff.

Learn more about platform capabilities and control-unit integration in Types of Controllers in CNC Machines Explained.

2025 Trends: AI-Driven HMI Design for Smarter CNC Devices

HMI Design for Manufactured Devices is moving from static screens to adaptive assistants—especially around CNCs where context changes rapidly.

What’s new and worth adopting

- Adaptive AI interfaces

- The HMI learns which widgets operators use by context (setup vs. production) and reorders tiles. It also predicts likely alarms and preloads guided fix steps.

- Voice and gesture controls

- Voice: “Show Offsets,” “Slow Feed 20%,” “Open Alarm History,” with confirmation prompts and role checks. Gesture: touchless next/prev for gloved operators.

- Predictive, sustainable design

- Dashboards show energy-per-part and tool-life forecasts, nudging behavior that cuts kWh and scrap. Ergonomic UI tweaks (contrast, motion reduction) lower fatigue.

- Modular HMI kits

- Radonix offers modular screen/panel kits—swap layouts by machine type while preserving core patterns. This shortens project timelines and enforces consistency across cells.

These trends help human-machine interface CNC solutions stay usable, safe, and efficient while your mix of machines and materials evolves.

Conclusion: Design Better Screens, Build Better Parts

HMI Design for Manufactured Devices is the fastest lever for safer, faster CNC operations. Start with real operator tasks, prototype quickly, and wire in diagnostics that cut recovery time.

When your screens fit hands, habits, and hazards, quality rises, and fatigue falls. Pair an evidence-based HMI with a capable CNC machine control unit and consistent CNC control panel functions across machines to unlock predictable performance.

Radonix can accelerate that journey with modular kits, SDKs, and proven patterns. Design superior HMIs for your CNC—start with Radonix tools at radonix.com

FAQ

Q1: What is HMI Design for Manufactured Devices?

A: It’s a user-centered approach to building interfaces for factory equipment. For CNCs, it blends ergonomics, real-time data from the CNC machine control unit, and consistent CNC control panel functions to reduce errors and training time.

Q2: Which tools should I use for CNC HMI prototyping?

A: Start in Figma for wireframes and interactive flows, then implement in Qt/QML for embedded performance. Pair with Radonix HMI SDKs to bind live CNC data early. This staged approach speeds HMI Design for Manufactured Devices from sketch to shop floor.

Q3: How do I handle glove use and glare on an HMI CNC control panel?

A: Use large, high-contrast targets (10–12 mm minimum), minimize fine gestures, add hard-key redundancy for critical actions, and apply anti-glare glass. These ergonomic HMI design choices improve accuracy and reduce fatigue.

Q4: What’s the best way to integrate with industrial CNC control systems?

A: Expose fieldbus diagnostics, servo following error, and interlocks directly in the HMI. Keep the control loop real-time and the UI asynchronous. Use standardized posts and macros across machines to maintain predictable CNC control panel functions.

Q5: How do AI and voice help HMI Design for Manufactured Devices?

A: AI can adapt layouts to context and recommend fixes during alarms; voice handles quick navigation (“show offsets,” “open alarms”) with confirmations. Together, they lower cognitive load and speed response without compromising safety.

Q6: How do I measure success after rollout?

A: Track KPIs: training time, MTTR, first-article pass rate, and alarm recurrence. If HMI Design for Manufactured Devices improved clarity and feedback, these metrics will trend in the right direction within weeks.

Contact Us:

- E-Mail: info@radonix.com

- Phone: +90 (553) 920 5500