Cloud and Remote Management of CNC Machines

CNC (Computer Numerical Control) machines are among the core components of modern industrial production, playing a critical role in improving precision, efficiency, and overall productivity. However, traditional management and monitoring methods for CNC systems have relied heavily on on-site supervision, requiring operators to be physically present near the machine.

This conventional approach often results in inefficiencies, increased downtime, and higher operational costs. To overcome these limitations, Cloud computing and remote management technologies are reshaping how CNC machines are monitored, analyzed, and optimized.

These next-generation solutions transform industrial workflows by centralizing data collection, enabling real-time analytics, and offering greater operational flexibility—all while supporting sustainable, cost-effective manufacturing.

Increasing Efficiency with Cloud-Based Solutions

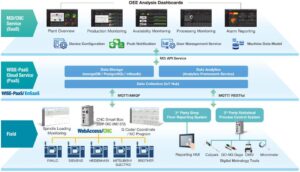

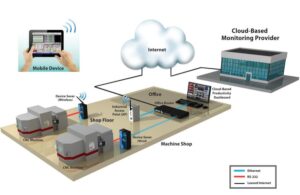

Cloud-based CNC management systems allow manufacturers to monitor, control, and analyze their machines from a centralized platform—no matter where the machines are located. Through seamless data transfer from the production floor to secure cloud servers, businesses gain access to real-time performance data, maintenance updates, and fault notifications.

By utilizing these tools, manufacturers can improve production planning, detect bottlenecks instantly, and ensure uninterrupted workflow across multiple facilities. Cloud platforms also facilitate predictive analytics, allowing early detection of performance degradation before it leads to costly downtime.

Example:

An automotive parts manufacturer integrated its CNC machine network into a cloud-based monitoring platform. This system continuously analyzed machine performance, detected inefficiencies, and automatically alerted operators to potential issues. As a result, unplanned downtimes were reduced by over 20%, and the company achieved better control over its production quality and scheduling.

Time and Cost Savings through Remote Management

Remote management systems empower engineers and production managers to control CNC machines via the internet, eliminating the need for on-site adjustments. From parameter tuning to process optimization, all operations can be executed securely from any location.

For companies managing multiple production lines or facilities, this capability is invaluable. Data from various machines can be aggregated and monitored in one interface, streamlining communication and enabling faster, more informed decision-making. Additionally, remote maintenance minimizes travel time and downtime, leading to significant operational cost savings.

Example:

A food manufacturing company implemented an IoT-based CNC remote management system to optimize its production workflow. Real-time feedback on spindle load, feed rate, and temperature was transmitted to a central dashboard. This allowed production supervisors to monitor performance remotely and intervene instantly when deviations occurred. Maintenance teams could also diagnose and address faults without visiting the plant, reducing downtime and improving output consistency.

Data Security and Performance Monitoring

As CNC systems become increasingly connected, data security has become a top priority. Cloud-based and remote management platforms must ensure the confidentiality, integrity, and availability of production data through advanced encryption and secure access control.

To maintain operational trust, leading manufacturers now combine cybersecurity protocols with AI-powered monitoring to detect unusual network activity or system vulnerabilities in real time. This approach ensures data remains protected while still allowing transparent performance analytics and reporting.

Example:

A steel production facility adopted an encrypted communication system for transmitting CNC performance data to its cloud platform. Access to the remote monitoring dashboard was restricted through multi-factor authentication and role-based permissions. This ensured that only authorized personnel could access sensitive data while maintaining continuous, real-time visibility of the production line’s performance and condition.

Integration and Future Opportunities

The integration of cloud and remote management solutions with CNC machines represents a major milestone in the transition toward smart, autonomous manufacturing. These systems enable deeper customization, cross-department connectivity, and intelligent decision-making.

In the near future, AI and machine learning algorithms will further enhance these platforms—enabling CNC machines to self-optimize cutting parameters, predict tool wear, and even autonomously schedule maintenance. Meanwhile, 5G technology will revolutionize data transmission speed, reducing latency and making real-time CNC control even more precise and reliable.

Example:

A precision engineering company deployed an AI-based remote management system to continuously analyze CNC data from its machining centers. The system automatically adjusted cutting speeds based on real-time load conditions, improving tool life and surface quality. It also predicted potential failures several hours in advance, allowing proactive maintenance. In the future, such systems will evolve toward fully autonomous CNC environments, requiring minimal human intervention.

Conclusion: A New Era in Industrial Production

Cloud-based and remote management solutions have ushered in a new era of smart manufacturing, transforming CNC operations from isolated systems into interconnected, intelligent production networks.

These technologies not only increase productivity and reduce costs but also enhance data visibility, sustainability, and security across industrial ecosystems. Manufacturers leveraging these systems can make faster, data-driven decisions, minimize resource consumption, and maintain continuous production with minimal downtime.

As cloud, IoT, and AI technologies advance, CNC machines will become more autonomous, adaptive, and efficient—paving the way for the next stage of industrial evolution. Businesses that embrace these innovations today will hold a decisive competitive advantage in the factories of tomorrow.

Contact Us:

- E-Mail: info@radonix.com

- Phone: +90 (553) 920 5500