Glass Processing

Radonix CNC controllers and interfaces, specifically designed for the glass processing industry, cover cutting, engraving, and water jet applications. Our systems, which provide high precision and efficiency, guarantee seamless operation for various processes.

Uygulama Alanları

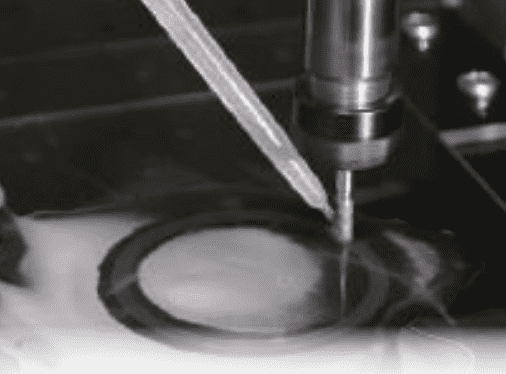

Cutting

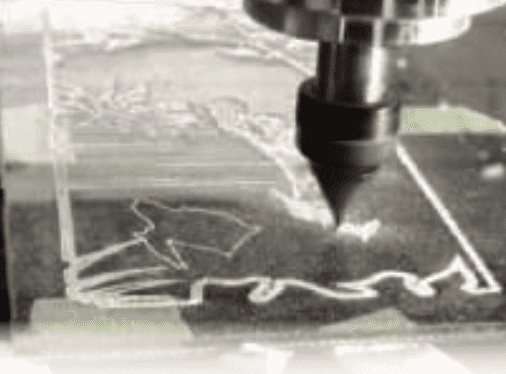

Engraving

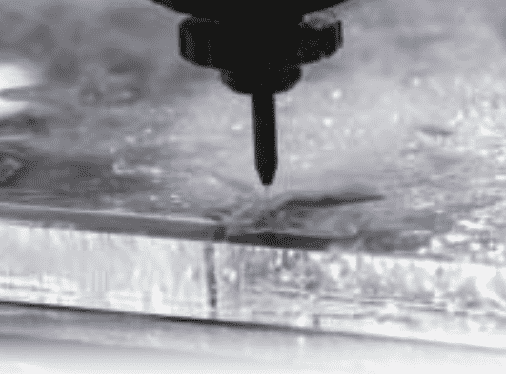

Water Jet

DESCRIPTIONS

Tangent Motion and C-Axis Integration: Provides support for complex cutting paths and shapes, ensuring high precision for advanced designs.

Automatic Referencing and Alignment: Automatically detects the zero point and aligns designs with the workpiece, reducing setup time and minimizing potential errors.

Automatic Pressure Adjustment: Maintains consistent tool pressure during glass cutting, reducing breakage risk and improving cutting quality.

Rotary Z-Axis Support: Accommodates special applications that require rotation settings, enabling advanced operations.

Continuous Material Management: Integrated loading tables and conveyor systems speed up processes, enhancing productivity.

Direct DXF Execution: Eliminates the need for G-code, allowing direct processing of design files and simplifying the workflow.

Real-Time Design Editing: Operators can modify scale, rotation, and orientation settings within the software, enhancing flexibility and precision.

Multi-Axis Water Jet Cutting: Offers precise control for complex cuts, including angled and beveled edges, using environmentally friendly water jet technology.

Smart Height Control: Optimizes the distance between the nozzle and the surface during processing, ensuring consistent quality across all material types.

Material Alignment Correction: Automatically adjusts for heavy or irregular glass sheets, improving accuracy and minimizing material waste.

Achieve superior precision and efficiency in cutting, engraving, and water jet operations with Radonix glass processing solutions!