AI Support in CNC Machines: An Industrial Revolution

Traditional CNC (Computer Numerical Control) machines have long been a cornerstone of the industrial manufacturing sector. However, with the rapid acceleration of digital transformation, AI (Artificial Intelligence)-powered CNC systems are revolutionizing manufacturing processes. The integration of AI into CNC machines significantly enhances production speed, efficiency, quality, sustainability, and competitiveness. This article aims to explore in detail the application areas, industrial benefits, and future possibilities of AI in CNC machines.

Application Areas of Artificial Intelligence in CNC Machines

Artificial intelligence adds various intelligent capabilities to traditional machining processes, enhancing the efficiency and adaptability of CNC machines. These application areas include smart automatic programming, real-time quality control, predictive maintenance, adaptive control systems, and energy optimization. Each of these topics redefines the role of CNC machines in industrial manufacturing.

1. Smart Automatic Programming

AI enhances CAD/CAM software, enabling the fast and accurate creation of programs necessary for production. In traditional CNC machines, operators manually create tool paths, while AI-powered systems can automatically determine the most optimal tool paths based on historical data and operator feedback. Additionally, AI continuously improves machining strategies based on historical data from the production process, enabling faster production with fewer errors.

2. Real-Time Quality Control

Quality control in CNC machines is often limited to post-processing measurements. However, AI-powered CNC machines analyze real-time data from sensors during production and automatically perform quality control. By using image processing and machine learning algorithms, surface roughness, tolerance deviations, and material defects can be detected. AI ensures early detection of errors, minimizing production defects, and guaranteeing the final product’s quality.

3. Predictive Maintenance

AI improves the maintenance processes of CNC machines. AI-powered systems monitor the condition of machine components and analyze performance data to predict potential failures. This allows more accurate scheduled maintenance and helps reduce unexpected downtime, labor losses, and maintenance costs. By monitoring parameters such as temperature, vibration, and energy consumption, AI can detect mechanical failures in advance.

4. Adaptive Control Mechanisms

CNC machines can be influenced by environmental factors and dynamic machine behaviors during processing. AI continuously analyzes parameters such as cutting forces, vibrations, and temperature, adjusting processing parameters accordingly. For example, when a cutting tool wears out or a change occurs in the process, AI optimizes processing speed and depth, extending tool life and ensuring a more efficient machining process.

5. Energy Management and Optimization

Energy efficiency is a critical factor in ensuring the sustainability of manufacturing processes and reducing costs. AI analyzes energy consumption and ensures machines operate more efficiently. AI algorithms can prevent unnecessary energy consumption during the process, optimize motor speeds, and minimize downtime. This not only reduces energy costs but also lowers environmental impact.

Industrial Benefits of AI-Powered CNC Machines

The integration of AI technology into CNC machines provides various significant industrial advantages. These benefits lead to significant improvements in production efficiency, quality control, flexibility, competitiveness, and sustainability.

1. Increased Productivity

AI-based optimization techniques can significantly shorten production times and allow for the production of more parts. AI-powered CNC machines achieve higher production volumes in shorter times through optimization during machining. This provides companies with faster product deliveries and lower production costs.

2. Reduced Error Rates

AI performs real-time data analysis to minimize errors in the production process. In CNC machines, machining processes are continuously monitored through a combination of image processing and sensor data. As a result, tolerance deviations and other production errors are detected and corrected instantly, improving product quality and reducing error rates.

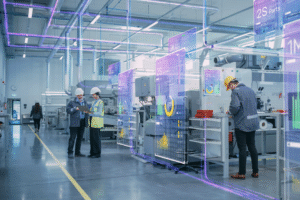

3. Enhanced Human-Machine Interaction

AI-powered interfaces allow operators to manage machines more effectively and efficiently. AI-based voice commands and augmented reality (AR)-supported maintenance systems reduce operators’ workload and make machine maintenance processes more user-friendly. This increases the workforce of operators while extending the machines’ service life.

4. Flexibility and Customization

AI plays an important role in customizing production processes. AI-powered CNC machines can quickly adapt to production demands and create personalized machining strategies. This feature provides flexible production capabilities across a wide range of applications, from mass production to low-volume custom manufacturing.

5. Competitive Advantage

AI-optimized production processes help companies gain a competitive edge in the market. AI-powered systems enable the production of high-quality products at low costs. Furthermore, the speed and flexibility provided by AI enable companies to respond to customer demands more quickly.

Future AI-Powered CNC Technologies

In the future, AI-powered CNC machines are expected to gain more autonomy. Systems integrated with deep learning algorithms and the Internet of Things (IoT) will create fully autonomous production lines. Additionally, digital twin technology, which tests production processes in virtual environments, will reduce costs while increasing efficiency in real production environments.

Quantum computing, advanced data analytics, and deeper integration of AI will enable the optimization of production processes with more complex analyses. AI-powered CNC machines will combine with autonomous robots to perform completely unmanned operations on production lines. These advancements will make future production systems more efficient, safe, and sustainable.

Conclusion

Artificial intelligence is transforming the manufacturing sector by increasing the efficiency, quality, and reliability of CNC machines. AI-powered systems, with capabilities like predictive maintenance, automatic quality control, and adaptive machining, help businesses become more sustainable and competitive. The integration of AI into CNC machines will become an indispensable element of the manufacturing sector in the future. These technologies, as pioneers of Industry 4.0 and 5.0, will continue to revolutionize production processes.

Contact Us:

- E-Mail: info@radonix.com

- Phone: +90 (553) 920 5500