By 2025, IoT in Smart Agriculture is projected to lift yields by up to 20% in farms that unify sensing, analytics, and automated actuation.

This article explores how to harness IoT in Smart Agriculture with CNC-grade motion control to automate tasks like precision planting, variable-rate irrigation, and drone-guided harvesting.

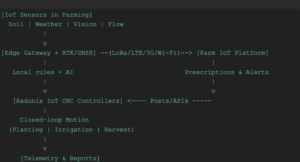

We’ll connect the dots between “smart farming IoT” telemetry, farm IoT platforms, and the deterministic motion that only CNC controllers can deliver—turning insights into repeatable, efficient actions across acres.

You’ll learn the fundamentals of IoT in Smart Agriculture, how iot cnc controllers orchestrate field operations, and how to design an operator-friendly interface with iot hmi design best practices.

We’ll also tackle connectivity and security challenges typical in industrial iot agriculture, and preview 2025 upgrades like edge AI for real-time crop monitoring and sustainable, CNC-driven machinery.

For control-layer background and product options, explore the Radonix blog and the product lineup for Radonix IoT CNC controllers.

Fundamentals of IoT in Smart Agriculture and CNC Synergy

IoT in Smart Agriculture merges IoT sensors in farming—soil moisture, EC/PH, canopy temperature, NDVI imaging, weather stations—with gateways and cloud analytics to guide interventions.

CNC automation for agriculture closes the loop: it executes precise, repeatable motions for planting, weeding, spraying, and harvesting based on live or forecasted data.

Core building blocks

- Sensing: Distributed soil probes, machine vision on booms, multispectral drone passes, and asset telematics.

- Connectivity: Field gateways using LTE/5G, LoRaWAN, or private Wi‑Fi; store-and-forward buffers for dead zones.

- Analytics: Farm IoT platforms delivering prescriptions (e.g., seed/flow maps) from historical and real-time data.

- Actuation: iot cnc controllers convert prescriptions into toolpaths and motion profiles for planters, sprayers, and autonomous implements.

Why CNC-level motion matters

- Deterministic control: Precise seeding depth, row spacing, and boom height via servo drive control.

- Closed-loop feedback: Encoders and GPS/RTK validate motion against plan; corrections happen instantly.

- Interoperability: Standardized posts, macros, and PLC integration enable consistent behavior across carriers and implements.

This synergy is the engine of IoT in Smart Agriculture: sensor-driven intelligence plus CNC-grade execution.

Role of IoT CNC Controllers in Smart Farming Automation

IoT in Smart Agriculture becomes operational when prescriptions are turned into motion. Here’s how iot cnc controllers drive farm tasks with speed and repeatability.

What iot cnc controllers do on the farm

- Ingest variable-rate maps (shapefiles/GeoJSON) for seed, fertilizer, or water.

- Fuse GNSS/RTK position, IMU, and implement encoders to localize accurately.

- Generate and execute toolpaths with closed-loop control: seeder actuation, boom section control, and cutter pathing for robotic harvesters.

- Stream telemetry to farm IoT platforms and adjust on the fly when sensors or AI models flag anomalies.

Numbered setup path: From sensors to actuation

- Sensor integration

- Connect soil moisture, vision cameras, and flow sensors to the gateway. Calibrate ranges and sampling rates.

- Data-driven pathing

- Load GIS prescriptions; align to RTK base corrections. IoT in Smart Agriculture workflows map zones to precise CNC toolpaths.

- CNC mapping and control

- In the controller, map inputs to outputs and axes: depth actuators, seed meters, section valves, and steering.

- Closed-loop execution

- Use encoder feedback and flow meters to verify commanded vs. actual rate/depth; correct deviations in real time.

- Reporting and learning

- Log per‑zone application and deviations; push to the cloud for model retraining and compliance reporting.

Table: Farm task integration with iot cnc controllers

| Farm Task | IoT CNC Function | Efficiency Boost |

| Precision planting | Variable-rate seeding with depth servo control and RTK row guidance | +8–15% seed efficiency; uniform emergence |

| Irrigation control | Variable-rate irrigation with flow/pressure feedback loops | −10–20% water use; higher WUE |

| Spot spraying | Vision-triggered nozzle actuation and boom height control | −40–80% herbicide use (weed-only targeting) |

| Autonomous mowing | Path planning with obstacle avoidance and blade RPM control | +20–30% labor savings, consistent cut |

| Drone-assisted harvest | Drone vision maps → CNC harvester path refinement | Faster pick/pack; reduced bruising |

| Fertigation | EC/PH sensors + valve PWM control for in-line dosing | Stable nutrient delivery; less runoff |

When choosing controllers, favor platforms designed for industrial iot agriculture: ruggedized enclosures, extended temp ranges, sealed connectors, and deterministic networking. For a ready lineup, see Radonix IoT CNC controllers.

Designing IoT HMI for Agricultural CNC Systems

Well-designed iot hmi design puts real-time data and control at operators’ fingertips—on cab tablets and remote dashboards—without overwhelming them. It’s key to scaling IoT in Smart Agriculture across fields and teams.

Design goals

- Clarity in the field: Strong contrast, large tap targets, offline-first caching (patchy signal).

- Role-based views: Operator (run status); Agronomist (prescriptions); Maintenance (telemetry, alerts).

- Actionable alarms: Plain-language messages with guided steps, not just codes.

Step-by-step: Build an effective IoT HMI

- Map stakeholders and tasks

- Identify who needs what: start/stop, section overrides, prescription swaps, diagnostics.

- Define core screens

- Run view: Map, current zone, setpoint vs. actual (seed/water), speed, following error.

- Equipment view: Axis states, valve status, pressure/flow gauges, encoder health.

- Alarm center: Severity, likely causes, step-by-step fixes, and “safe resume” button.

- Offline-first architecture

- Cache prescriptions locally; queue logs for later sync. Show connectivity status clearly.

- Safety and overrides

- Guarded E-stop, speed limiting, and geo-fenced no-go areas. Log overrides with user IDs.

- Mobile and remote monitoring

- Deliver a responsive web dashboard for supervisors. Summaries by field, implement, and operator.

- Iteration and training

- Use field ride-alongs to refine UI flows. Offer “simulation mode” for training new operators.

Case study: Vineyard irrigation, 15% water savings

- Context: A hillside vineyard with variable soils deployed soil probes and a weather station.

- Action: Using Radonix IoT CNC controllers, the team built an iot hmi design showing zone maps, real-time flow, and valve states. Edge logic adjusted drip rates by zone using moisture setpoints and ET forecasts, with alerts for line pressure anomalies.

- Result: 15% season water savings and more consistent berry size year-over-year, validated through block yield analysis.

Challenges and Solutions in IoT-Enabled Farm CNC Automation

IoT in Smart Agriculture faces real-world friction. Here are common hurdles and how to mitigate them.

- Rural connectivity gaps

- Solution: LoRaWAN for local sensor backhaul; store-and-forward gateways; opportunistic LTE/5G sync at field edges or barns.

- Harsh environments

- Solution: IP65+ enclosures, conformal-coated PCBs, MIL-spec connectors, and shock mounts for CNC controllers and HMIs.

- Cybersecurity and data privacy

- Solution: Device identity, TLS everywhere, role-based access, VPN for remote support, and OTA updates with signed firmware.

- Interoperability chaos

- Solution: Support ISOBUS/ISO 11783 and open APIs. Adopt farm IoT platforms that accept standard telemetry and map layers.

- Power management

- Solution: Hybrid power (PTO/alternator + battery); sleep modes; energy-aware scheduling to align with peak/valley power pricing.

- Scaling across fields and fleets

- Solution: Provisioning scripts, templated configurations, and centralized policy for alarms and overrides. Use Radonix fleet tools to clone settings across machines quickly.

- Data governance

- Solution: Clear policies on data ownership, anonymization for benchmarking, and retention aligned to regulatory needs.

These practices keep IoT in Smart Agriculture robust while you scale from a pilot row to hundreds of hectares.

2025 Trends: AI and Sustainability in IoT Smart Agriculture

The next wave of IoT in Smart Agriculture adds intelligence and accountability to every pass.

What’s emerging now

- Edge AI for crop monitoring

- On-device models classify weed pressure, detect disease onset, and predict irrigation needs with low latency.

- Adaptive, sustainable pathing

- AI-optimized routes reduce overlap, fuel burn, and soil compaction; CNC motion fine-tunes acceleration and speed profiles to save energy.

- Drone-CNC hybrids

- Drones scout and update prescriptions; implements adapt routes and rates within minutes, not days.

- Carbon-aware operations

- Dashboards tally CO2e per task; controllers schedule energy-intensive operations during renewables-heavy grid windows.

Table: 2025 trend comparisons for IoT in Smart Agriculture

| Trend | What it enables | Sustainability Impact | 2025 Readiness |

| Edge AI crop inference | Weed/disease detection; VRA updates on the fly | Fewer pesticide passes | High (mature models) |

| Energy-aware motion | Optimized acceleration/overlap | Lower fuel and battery use | Medium–High |

| Drone-to-implement loop | Rapid, localized prescriptions | Less waste, timely response | Medium (workflow) |

| Carbon metrics per task | Decisions with CO2e visibility | Incentivizes efficient ops | Medium |

Radonix advantage

- Radonix IoT CNC controllers pair closed-loop motion with edge analytics and open APIs, accelerating the move to AI-informed, sustainable farm routines without locking you into a single vendor.

IoT Workflow: From Field Sensing to CNC Execution

A compact view of how data flows in IoT in Smart Agriculture.

This is the heartbeat of IoT in Smart Agriculture: measure, decide, act, learn.

Conclusion: Precision Agriculture Needs Precision Motion

IoT in Smart Agriculture is shifting from pilots to production. The farms winning on yield and sustainability unify high-quality sensing, analytics, and deterministic execution. CNC-grade motion control bridges the last mile—turning prescriptions into accurate, repeatable fieldwork at scale. With robust iot cnc controllers, thoughtful iot hmi design, and standards-based integration, you can automate planting, irrigation, and harvesting while saving inputs and protecting soil health.If you’re ready to pilot IoT in Smart Agriculture with CNC reliability, start small—one block, one task—and scale with the results.Transform your farm with IoT in smart agriculture—integrate Radonix CNC at radonix.com

FAQ

Q1: What are the key benefits of IoT in Smart Agriculture?

A: Higher yields through targeted interventions, reduced inputs via variable-rate control, and better timing using real-time telemetry. When paired with CNC automation for agriculture, plans translate into repeatable actions that save water, seed, fuel, and labor.

Q2: How do iot cnc controllers differ from traditional farm controllers?

A: They add closed-loop motion control with encoder feedback, precise path planning, and deterministic timing—vital for tasks like seeding depth and boom height. They integrate with farm IoT platforms while maintaining industrial reliability.

Q3: What connectivity works best for fields with poor coverage?

A: A hybrid: LoRaWAN for local sensors, buffered gateways, and LTE/5G uplinks where available. Edge analytics keep operations moving when the cloud is out of reach—critical for IoT in Smart Agriculture.

Q4: How does iot hmi design improve operator outcomes?

A: Clear, role-based screens surface the right data—setpoints vs. actuals, alarms with fixes, and safe overrides. Mobile dashboards enable remote oversight and training, speeding response and reducing errors.

Q5: Can IoT in Smart Agriculture help sustainability goals?

A: Yes. Variable-rate application and energy-aware motion reduce inputs and fuel. Dashboards quantify savings, and AI models optimize timing. CNC-grade execution ensures planned efficiencies actually happen in the field.

Q6: What’s a good first project to pilot?

A: Variable-rate irrigation on a single block or precision planting on a test strip. Instrument, build prescriptions, map to Radonix IoT CNC controllers, and compare yield and input use to your baseline.

Contact Us:

- E-Mail: info@radonix.com

- Phone: +90 (553) 920 5500