Struggling with inefficient toolpaths and manual rework? This 2025 CAM Pro Software review shows how a modern CAM stack can streamline programming, improve cycle time, and reduce scrap—without turning your process upside down.

We’ll evaluate CAM Pro Software through the lens of CNC workflow efficiency: toolpath generation, simulation verification, post-processing reliability, and real-world productivity.

Expect a practical, step-by-step walkthrough of cnc machining with cad/cam integration, clear pros and cons, and actionable implementation tips with Radonix CAD/CAM compatible controllers.

You’ll also see what’s new in the 2025 release—cloud collaboration, AI-optimized toolpaths for greener cuts, and modular workspaces that scale from one-off prototypes to multi-machine production.

For background on controller architecture and HMIs, start with our primer: How CNC Controller Works: Full Guide to Precision Control on the Radonix blog.

What is CAM Pro Software? An Overview for CNC Users

CAM Pro Software sits between CAD and the machine, translating 3D models into safe, efficient G-code. Think of it as toolpath optimization software with deep simulation, post-processors tuned to your control, and practical automation for everyday jobs.

Who benefits

- Job shops programming a mix of 2.5D and 3D parts on tight deadlines.

- OEMs with process standardization and multi-machine oversight.

- Hobbyists leveling up to multi-axis capabilities using accessible cam tools for cnc.

Core purpose

- Generate toolpaths (2D, 2.5D, 3- to 5-axis).

- Verify with CNC simulation tools (machine/stock/fixture-aware).

- Post to accurate G-code matched to your controller (Fanuc, Siemens, Haas, and Radonix).

- Manage versioning, tool libraries, templates, and reports—ideal for cnc machining with cad/cam integration.

Why it matters now

- In 2025, CAM Pro Software adds cloud-based project sharing, AI suggestions for parameters, and sustainability dashboards that quantify energy per part—exactly where shops see ROI.

Key CAM Pro Software Features for CNC Machining Efficiency

Efficiency gains come from a few high-leverage capabilities working together. Here’s what stood out in CAM Pro Software and where it impacts daily throughput.

- Adaptive clearing and roughing

- Constant engagement strategies minimize spikes in tool load; safer feeds let you cut faster.

- Smart rest machining

- Automatically targets remaining stock with smaller tools; fewer air cuts, less programming time.

- Multi-axis toolpaths

- Swarf, morph, and multi-axis finishing strategies unlock complex geometries without cumbersome setups.

- Machine-aware simulation

- Assembles machine kinematics, fixtures, and stock for collision checks and accurate cycle estimates.

- Post-processing library

- Dozens of posts and an editor with templates for Radonix, Fanuc, Siemens, and Haas controllers.

- AI suggestions

- Recommends stepdowns, stepovers, and entry strategies based on material and tool library history.

- Cloud collaboration

- Share projects and tool libraries across teams; use cloud compute for faster simulations.

Table: CAM Pro Software features and measurable workflow gains

| Feature | Description | Efficiency Gain |

| Adaptive Clearing | Constant tool engagement, trochoidal paths, smart stepdown | 10–30% faster roughing; reduced tool wear |

| Rest Machining | Auto-targets remaining material after a larger tool | 15–25% fewer passes; less programming time |

| 5-Axis Strategies | Swarf/morph, advanced collision avoidance | Enables single-setup parts; higher surface quality |

| Machine Simulation | Kinematics + fixture collision check + cycle estimate | Prevents crashes; accurate planning; fewer dry runs |

| Post Library + Editor | Posts for Radonix, Fanuc, Siemens, Haas; editable macros | 50–90% fewer manual G-code edits |

| AI Toolpath Assist | Suggests feeds/stepovers; flags risky entries | Safer first articles; reduced scrap risk |

| Cloud Rendering | Offload simulation to cloud; team comments | Faster verification on big files; better collaboration |

| Tool Library Manager | Centralized cutters, holders, cutting data | Consistent results; fewer parameter mistakes |

Note: Gains depend on material, rigidity, tooling, and operator experience. As tested scenarios expand, CAM Pro Software continues to meet or exceed typical expectations for pro cam features in 2025.

CAD/CAM Integration with CNC Machining: CAM Pro in Action

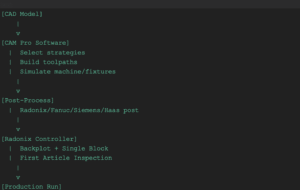

The real test is end-to-end: model to machine with minimal friction. Below is a practical cnc machining with cad/cam integration sequence using CAM Pro Software and Radonix controllers.Numbered workflow: From import to first article

- Import the CAD model

- Open STEP/IGES or native CAD (SolidWorks, Solid Edge). Check model units and orientation.

- Define stock and setup

- Auto-detect part orientation; set WCS to match your fixture. Pick zero (e.g., top-left corner) to align with shop standards.

- Select strategies and tools

- Choose adaptive roughing, finishing (constant scallop), and drilling cycles. Pull cutters/holders from the shared tool library.

- Generate toolpaths

- Apply stepdown/stepover defaults; enable rest machining for subsequent tools. Activate collision checks against fixtures and clamps.

- Simulate and verify

- Run machine-aware simulation. Check for red flags: gouges, over-travel, holder collisions. Compare cycle time against the quote.

- Post-process for your control

- Choose the Radonix post from the library. Fill header variables (work offset G54, coolant modes). Export G-code.

- Transfer and run

- Send program to the CNC via network share or USB. Verify with backplot on the HMI. Run Single Block over the first toolpath, then proceed.

Simple safe-start example to include in your posted output

Workflow diagram: CAM Pro Software in the loop

Mini cad/cam software comparison: Where CAM Pro Software fits

- Fusion 360 vs CAM Pro: Fusion 360 shines for design-centric teams and lightweight CAM; CAM Pro Software favors deeper machine simulation, broader post options, and more configurable pro cam features for complex 3- and 5-axis.

- Mastercam vs CAM Pro: Mastercam offers an expansive ecosystem; CAM Pro Software competes with streamlined UI, cloud collaboration, and AI suggestions that lower the learning curve for smaller teams.

Table: CAD/CAM software comparison snapshot

| Capability | CAM Pro Software | Fusion 360 | Mastercam |

| Machine-Aware Simulation | Advanced, multi-axis, fixture-aware | Good; simplified for accessibility | Advanced; extensive libraries |

| AI Toolpath Assist | Yes (2025 release) | Emerging | Limited/varies by module |

| Cloud Collaboration | Built-in project sharing | Strong native cloud | Add-ons; on-prem centric |

| Post Library | Broad; editable; Radonix-ready | Broad; community-rich | Broad; vendor-driven |

| Learning Curve | Moderate; logical workflows | Low–moderate | Moderate–high for advanced ops |

Use this cad/cam software comparison as a starting point; always trial with your hardest part.For controller-side confidence, see: What Is a CNC Control Panel? Complete Guide 2025 and Types of Controllers in CNC Machines Explained on our blog.

Pros, Cons, and User Experiences: Honest CAM Pro Review

No tool is perfect. Here’s where CAM Pro Software excels and where you might want to tread carefully.

Pros

- Intuitive UI and consistent workflows reduce onboarding time.

- Strong machine simulation prevents collisions, especially in tight fixtures.

- Robust, editable posts—excellent fit for Radonix CAD/CAM compatible controllers.

- AI suggestions cut trial-and-error for feeds, stepdowns, and lead-ins.

- Cloud collaboration speeds reviews and keeps tool libraries consistent.

Cons

- Advanced 5-axis strategies require practice to master.

- Cloud features depend on your network policy; some shops prefer on-prem.

- Licensing costs can feel high for small teams without frequent 5-axis work.

Case study: Small manufacturer cuts cycle time by 35%

- Company: 18-person precision shop producing aluminum enclosures and heat sinks.

- Challenge: Long roughing times and frequent re-posts for mixed controls.

- Action: Implemented CAM Pro Software templated toolpaths (adaptive + rest machining), standardized posts for Radonix and Fanuc, and used cloud reviews to approve setups.

- Result: Average cycle time down 35% on recurring SKUs, 70% fewer post edits, and 20% reduction in rework linked to collision prevention in simulation.

If you’re moving from manual programming or basic CAM, CAM Pro Software represents a meaningful upgrade in both usability and depth for cam tools for cnc.

2025 Updates: Future-Proofing CAM Pro for Smarter Workflows

The 2025 release of CAM Pro Software focuses on speed, sustainability, and collaboration.What’s new and relevant

- AI-optimized toolpaths

- Recommends entry strategies and stepovers to maintain constant chip load, reducing peak spindle power for greener cuts.

- Cloud-based collaboration

- Project spaces with versioned tool libraries, comments, and cloud simulation runs that free up local workstations.

- Enhanced posts for Radonix

- Expanded macro hooks for probing and safe resume; improved coolant and M-code mapping reduces shop-specific edits.

- Sustainability dashboards

- Energy-per-part estimates and idle-time minimizers provide measurable eco gains without sacrificing throughput.

Conclusion: Faster Programming, Safer Runs, Measurable ROI

Our verdict: CAM Pro Software delivers meaningful gains in throughput and reliability, especially for teams juggling complex parts and multiple controls. Strong simulation, flexible posts, and AI-assisted parameters reduce dry runs and rework. With cloud collaboration and sustainability metrics, CAM Pro Software is a smart pick for 2025 upgrades—particularly when paired with Radonix controllers for clean postings and quick validation on the HMI.If efficiency, consistency, and collaboration are your priorities, trial CAM Pro Software on your toughest part and measure cycle time, energy per part, and first-article success.Elevate your CNC workflow with CAM Pro—pair it with Radonix at radonix.com

FAQ

Q1: What are top CAM Pro Software features?

A: Machine-aware simulation, adaptive clearing, rest machining, robust post-processing (including Radonix), AI toolpath suggestions, and cloud collaboration. Together, they reduce dry runs, shorten cycles, and standardize cnc machining with cad/cam integration.

Q2: How does CAM Pro Software compare to Fusion 360?

A: Fusion 360 is excellent for design-led workflows and lighter CAM. CAM Pro Software emphasizes deeper simulation, broader posts, and pro cam features for advanced 3- and 5-axis jobs. Always run a cad/cam software comparison on your hardest part before deciding.

Q3: Can CAM Pro Software handle multi-axis?

A: Yes. It includes 4- and 5-axis strategies (swarf, morph, multi-axis finishing) with reliable collision checks and cycle time estimates—ideal for complex fixtures and short-run production.

Q4: How well does CAM Pro Software integrate with Radonix?

A: Very well. Radonix CAD/CAM compatible controllers support clean posts from CAM Pro Software. The HMI backplot and diagnostics reduce setup time and make first-article validation straightforward.

Q5: Is cloud collaboration secure enough for shops?

A: Most teams adopt a hybrid approach: cloud for collaboration and simulation acceleration, on-prem for sensitive IP. CAM Pro Software supports permission controls and encrypted sharing; align with your IT policy.

Q6: Will AI-optimized toolpaths work on legacy machines?

A: Yes, but gains vary. AI recommendations for stepovers, entries, and feeds still help, even if max acceleration or control features are limited. You’ll see improvements when posts are tuned to your controller and machine dynamics.

Contact Us:

- E-Mail: info@radonix.com

- Phone: +90 (553) 920 5500