Development of Multi-Axis CNC Controllers — Shaping the Future of Precision Manufacturing

The development of multi-axis CNC machines has transformed industrial production by merging precision, flexibility, and automation. Early CNC systems in the 1950s were limited to two axes, but modern machines now operate with 3, 4, 5, or even 6 axes, allowing complex geometries to be machined with unmatched accuracy.

This evolution has enabled manufacturers to achieve faster cycle times, higher precision, and greater design freedom — key pillars of today’s smart manufacturing era.

Role of CAD/CAM Software

A major milestone in CNC evolution was the integration of CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software. CAD allows engineers to model complex parts in 3D, while CAM converts these designs into executable machining instructions.

This digital synergy ensures:

- Seamless transfer from design to production.

- Faster programming of toolpaths.

- Reduced human error and improved part quality.

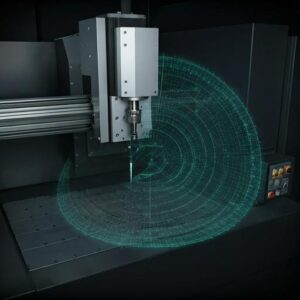

With CAD/CAM integration, manufacturers can visualize and simulate machining processes before production, minimizing waste and enabling the rapid, precise creation of intricate parts.

Digital Control and Artificial Intelligence

The adoption of digital control systems and AI-driven optimization has revolutionized CNC precision. Digital control allows electronic signals to manage tool movements in real time, providing a level of accuracy previously impossible with mechanical systems.

Artificial intelligence enhances these capabilities by:

- Monitoring machine performance and tool wear.

- Suggesting real-time parameter adjustments.

- Predicting maintenance needs to prevent downtime.

Together, digital systems and AI ensure autonomous optimization, maximizing efficiency and consistency across production lines.

Basic Principles of Multi-Axis CNC Controllers

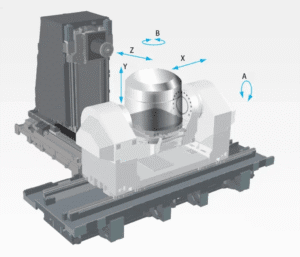

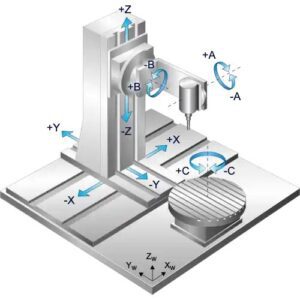

Multi-axis CNC machines synchronize movements across multiple axes — X, Y, Z, A, B, and beyond — enabling simultaneous machining from multiple directions. This coordination allows complex surfaces and 3D geometries to be produced without manual repositioning.

Coordinate Systems and Motion Control

Each axis in a CNC machine corresponds to a coordinate within a defined spatial system. Linear movements occur along the X, Y, and Z axes, while rotational movements take place along A, B, or C axes.

Advanced algorithms calculate and synchronize these motions precisely, ensuring that even the most intricate shapes are machined within micron-level tolerances. Proper motion control reduces vibration, improves tool life, and guarantees smooth surface finishes.

Synchronization and Dynamic Calculations

Accurate synchronization between axes is vital for maintaining precision in complex machining. CNC controllers perform dynamic calculations in real time, adjusting tool movements to maintain perfect alignment.

This allows:

- Real-time corrections to prevent dimensional errors.

- Consistent speed control across all axes.

- Improved geometry accuracy on complex parts.

Synchronization ensures that every axis moves harmoniously, enabling faster machining without sacrificing quality.

Digital Control and Feedback Systems

Modern CNC systems rely on feedback loops that constantly monitor and correct machine performance. When a deviation occurs, sensors instantly detect it, and the controller issues corrective commands.

Benefits of feedback systems:

- Error-free production: Real-time corrections prevent defects.

- Improved positioning: Ensures exact alignment and tool path accuracy.

- Process stability: Maintains consistent machining quality under high-speed conditions.

By leveraging digital control and sensor-based feedback, manufacturers achieve consistent, repeatable precision at every production stage.

Applications of Multi-Axis CNC Controllers

Multi-axis CNC machines are indispensable in industries demanding complex geometries and extreme accuracy. They deliver efficiency and speed across a wide range of materials and production volumes.

Aerospace Industry

In the aerospace sector, components must meet strict standards for performance, safety, and durability. Multi-axis CNC machines excel at machining titanium, aluminum alloys, and composites used in aircraft engines, wings, and spacecraft parts.

They enable:

- Micron-level precision in critical flight components.

- Rapid prototyping for testing new designs.

- Scalable mass production for consistent part replication.

This technology ensures that aerospace manufacturers meet the highest global standards for quality and safety.

Automotive Industry

Automotive manufacturers depend on multi-axis CNC systems for high-precision machining of engine components, chassis structures, and safety-critical parts.

Key applications include:

- Engine block and cylinder head machining.

- Prototyping for new vehicle models.

- Cost-efficient mass production with consistent tolerances.

These systems provide the perfect balance between speed, cost-effectiveness, and precision — essential for modern automotive design and production.

Medical Industry

In the medical field, multi-axis CNC machines are vital for producing implants, prosthetics, and microsurgical instruments. Each part must meet exact anatomical and biocompatibility standards.

Multi-axis systems allow manufacturers to:

- Machine custom implants with anatomical precision.

- Maintain smooth surface finishes for biocompatibility.

- Produce micro-scale instruments with exceptional accuracy.

These systems ensure both patient safety and high functional performance in critical medical applications.

Defense Industry

The defense sector relies on multi-axis CNC machining for weapons components, optical systems, and precision mechanisms that must perform reliably under extreme conditions.

Advantages include:

- High structural integrity for mission-critical parts.

- Extreme precision in machining complex shapes.

- Enhanced durability under operational stress.

From aircraft to ground vehicles, CNC technology ensures that all defense-grade components meet uncompromising quality standards.

Wood and Plastic Processing

In wood and plastic processing, multi-axis CNC machines provide both efficiency and creativity. These systems are used to craft decorative panels, furniture, and complex custom designs.

Their ability to perform detailed cuts, engravings, and 3D shapes makes them ideal for creative manufacturing and high-end product design. The result is precision craftsmanship with reduced waste and faster turnaround times.

Advantages of Multi-Axis CNC Controllers

Multi-axis CNC controllers deliver superior precision, efficiency, and flexibility, making them essential tools in modern manufacturing.

Enhanced Accuracy and Precision

With simultaneous multi-axis movement, these machines achieve micron-level accuracy in complex geometries. This capability is vital for sectors like aerospace and automotive, where even minor deviations can affect performance.

The ability to handle intricate shapes within one setup ensures flawless results both functionally and aesthetically.

Capability for Complex Designs

By combining linear and rotational movements, multi-axis CNC machines make it possible to produce shapes impossible with traditional systems. They efficiently handle advanced materials like titanium, composites, and alloys, expanding design potential while maintaining accuracy.

This flexibility supports industries that demand innovative and lightweight components with precise tolerances.

Reduced Repositioning and Setup Time

Multi-axis machines minimize workpiece repositioning, eliminating delays and reducing potential errors between setups.

Key outcomes:

- Shorter cycle times.

- Improved accuracy.

- Lower production costs.

Single-setup machining streamlines production, saves labor, and boosts manufacturing throughput.

Increased Efficiency and Throughput

By performing multiple operations simultaneously, multi-axis CNC systems significantly shorten production times. They support continuous, uninterrupted machining — ideal for mass production environments where consistency and speed are critical.

High-speed synchronization across axes enables manufacturers to achieve both volume and quality without compromise.

Conclusion — Radonix Multi-Axis CNC Innovation

Radonix leads the next generation of multi-axis CNC control systems, delivering unmatched precision, automation, and digital intelligence.

By integrating AI-based optimization, real-time feedback, and advanced motion algorithms, Radonix enables manufacturers to produce complex parts faster, safer, and more sustainably.

From aerospace to defense and beyond, Radonix continues to shape the evolution of CNC technology — empowering industries to reach new standards of performance, accuracy, and innovation.

Contact Us:

- E-Mail: info@radonix.com

- Phone: +90 (553) 920 5500