The Fusion of Tradition and Innovation

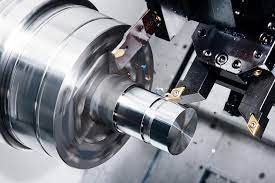

In a rapidly advancing manufacturing landscape, hybrid CNC control systems are redefining what’s possible in machining. These systems seamlessly blend the precision and artistry of manual machining with the speed, accuracy, and automation of modern CNC technology. The result is a solution that preserves the craftsmanship of traditional methods while meeting the demands of high-efficiency production.

By integrating manual control capabilities with CNC automation, hybrid systems give manufacturers the flexibility to adapt quickly to diverse production needs—making them a cornerstone of the next generation of smart manufacturing.

Embracing Tradition in Modern Machining

Hybrid CNC control systems act as a bridge between two worlds: the intuitive craftsmanship of human machinists and the programmed precision of computer-driven operations. Instead of replacing traditional skills, they enhance them.

Key Benefits of Hybrid Integration

- Creative control: Operators can apply hands-on expertise for complex detailing or one-off parts.

- CNC precision: Automated systems ensure consistency, speed, and accuracy for repetitive operations.

- Adaptability: Users can shift between manual and CNC modes based on project complexity or volume.

This synergy allows manufacturers to produce parts with the artistic precision of traditional machining, backed by the reliability and repeatability of CNC automation.

The Best of Both Worlds: Precision Meets Flexibility

A major strength of hybrid CNC systems lies in their ability to offer both manual and automated control without compromise. This hybrid approach provides greater control over every stage of machining—from creative prototyping to high-speed production.

Practical Advantages

- Complex part handling: Ideal for projects requiring intricate craftsmanship and precise tolerances.

- Automation on demand: Repetitive, time-intensive operations can be handled automatically.

- Error reduction: Smart control algorithms minimize operator fatigue and human error.

- Productivity boost: Switching between manual and automated modes streamlines workflow.

By merging traditional experience with intelligent automation, hybrid CNC systems empower operators to maximize both quality and output.

Versatility in Manufacturing

Hybrid CNC systems shine where flexibility and customization are key. Their dual-mode functionality allows manufacturers to meet a wide range of production requirements without extensive setup changes.

Capabilities that Drive Value

- Quick mode transitions: Easily switch from manual milling to CNC machining with minimal reprogramming.

- Custom and small-batch adaptability: Perfect for limited-run parts or prototypes requiring human finishing touches.

- Reduced downtime: Operators can make quick manual corrections without interrupting automated cycles.

This versatility supports industries that balance high precision with creativity—ensuring productivity without sacrificing individuality.

Cost-Efficient Modernization

For many facilities, replacing entire fleets of machines with full CNC systems isn’t feasible. Hybrid CNC control systems offer a cost-effective pathway to modernization.

Why It Makes Financial Sense

- Retrofitting legacy machines: Upgrade existing manual equipment with CNC functions.

- Lower capital investment: Avoid full replacements while still achieving automation benefits.

- Extended equipment lifespan: Preserve valuable machinery while improving functionality.

Hybrid retrofits are especially appealing for small and medium-sized manufacturers looking to enhance precision, reliability, and throughput without overwhelming budgets.

Developing Operator Skills: The Human Element Remains Vital

While automation continues to expand, hybrid CNC systems ensure that human expertise remains central to manufacturing. They empower machinists to combine intuition with data-driven control.

Workforce Advantages

- Skill enrichment: Operators stay actively involved, learning advanced CNC programming and digital monitoring.

- Higher engagement: Hands-on interaction fosters ownership and pride in the finished product.

- Balanced expertise: Teams develop both traditional craftsmanship and modern technical proficiency.

Rather than replacing workers, hybrid CNC systems elevate human potential—encouraging a more motivated and skilled workforce.

Industry Applications

Hybrid CNC technology is now being adopted across sectors that require both precision and adaptability.

Key Industries Benefiting from Hybrid CNC

- Aerospace: Enables the precise fabrication of complex components with manual intervention for final finishing.

- Automotive: Balances mass production with custom part prototyping and short-run manufacturing.

- Medical: Supports the production of customized implants and instruments with exacting accuracy.

From fine-tuned craftsmanship to data-driven machining, hybrid CNC control systems offer flexibility suited to both specialized and large-scale applications.

Looking Ahead: The Future of Hybrid CNC

As industries adopt technologies like AI, IoT, and predictive maintenance, hybrid CNC control systems are evolving into intelligent, connected platforms. These next-generation systems will:

- Enable real-time performance monitoring and error detection.

- Integrate machine learning to adapt machining strategies dynamically.

- Improve uptime through predictive maintenance analytics.

- Facilitate digital twin simulations for optimized workflows.

The future is one where craftsmanship meets computation, allowing hybrid CNC systems to redefine efficiency, precision, and creativity all at once.

Conclusion: Harmony Between Heritage and High-Tech

Hybrid CNC control systems embody the perfect balance between tradition and innovation. They enable manufacturers to preserve the tactile artistry of manual machining while achieving the consistency and efficiency demanded by modern production.

By combining hands-on craftsmanship with smart automation, hybrid CNC systems deliver higher productivity, lower costs, and exceptional quality—all while keeping skilled machinists at the heart of the process.

About Radonix

At Radonix, with over 16 years of expertise in CNC controller design and industrial automation, we develop solutions that empower manufacturers to modernize efficiently. Our control systems ensure smooth integration between legacy machinery and cutting-edge CNC technology—helping industries across the globe maintain excellence through innovation.

📧

📞